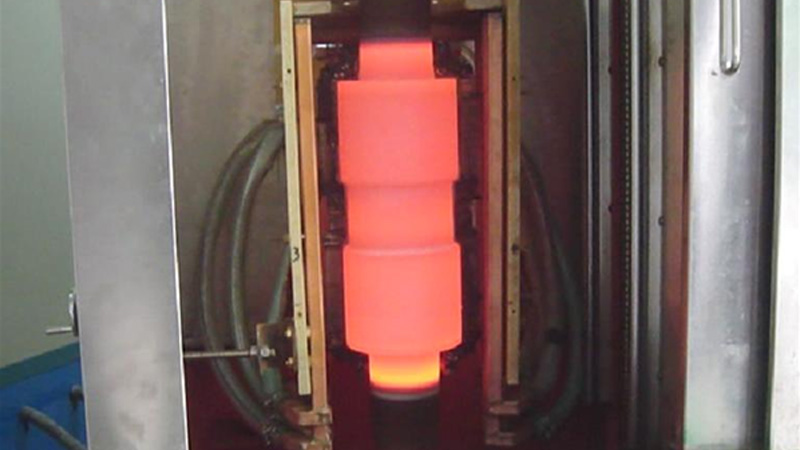

Different production lines need to pay attention to different things. When using hardening equipment, the following matters need to be noted.

1. Pay attention not to lack of water

When using the automatic quenching equipment , it is necessary to cooperate with the cooling water, but if the quality of the cooling water is not good, it will easily lead to rust and scale inside the equipment and pipeline blockage, and even directly lead to the damage of the quenching equipment and cannot work normally. Therefore,we must pay attention to the lack of cooling water and ensure that the cooling water is clean and free of impurities.

2. Pay attention to keep the circuit intact

There are many circuits in the automatic quenching equipment , if the circuit problems will lead to more serious failures of the equipment, therefore, when using the quenching equipment must pay attention to protect all the circuits, to check regularly, especially the induction coil circuit, but also to avoid short circuit between the induction coil and the workpiece when quenching.

3. The temperature of cooling water

The temperature of the cooling water is very important to the cooling effect after quenching of the workpiece. Therefore, we must pay attention to controlling the temperature of the cooling water, and do not turn off the cooling water in the gap between stopping work. For applications with a load persistence rate of 100%, the water temperature of the cooling water should be lower than 40℃ And if conditions permit, you’d better use soft water.

Fill in the information and we will contact you as soon as possible