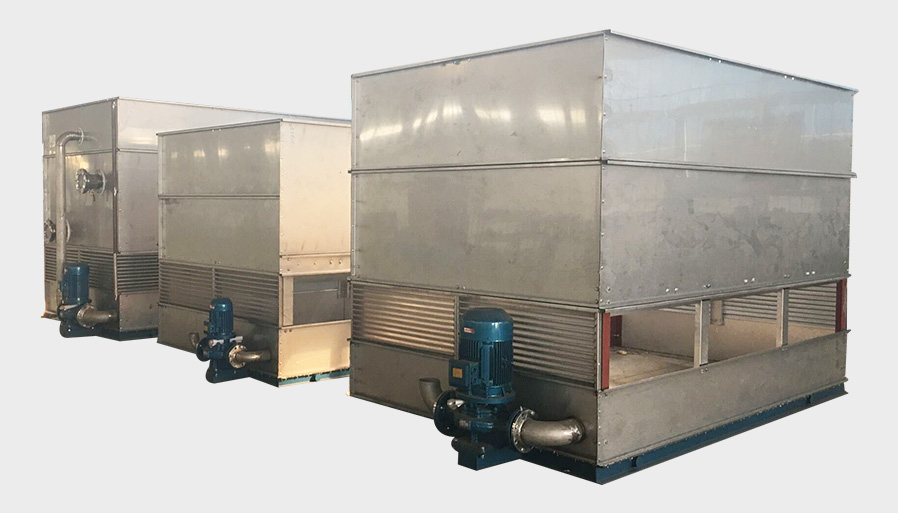

It is tube heat exchange placed in the tower to ensure the cooling effect through the heat exchange of circulating air,spray water outside the pipe, and circulating water inside the pipe. The circulating water is closed in the pipe, it can guarantee the water quality from pollution, protect the efficient operation of the main machine, improve the service life. When the outside air temperature is low, the sprinkler system can be stopped to save water. Water cooling tower has been widely used in steel metalluygy, mechanical processing, air conditioning system, and other industrial in recent years.

1. Low temperature automatic shut down sprinkler pump or fan system with special water collector, to achieve electricity and water-saving.

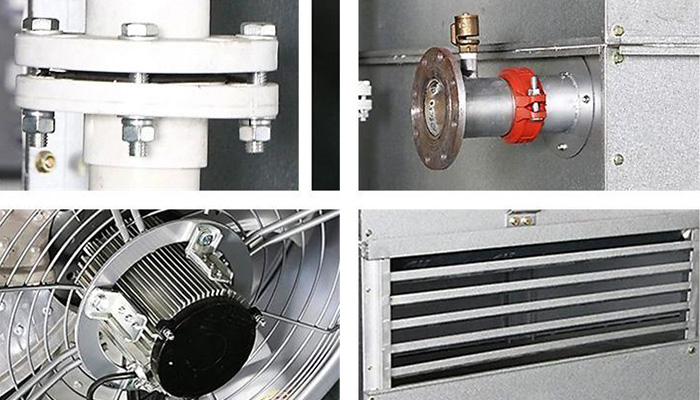

2. The selection of high performance aluminum and zinc plating corrosion plate, coil after acid washing passivation, the use of automatic welding machine, welding seam no leakage, high pressure resistance.

3. Closed circulation, no impurities, circulating medium for pure water, will not produce a scaling phenomenon, maintenance costs are low.

4. Automatic digital temperature control, support the dry operation mode without spray in winter, can also choose manual/automatic start fan or spray system according to the water outlet temperature, realize water and electricity saving, reduce the operation cost.

5. High quality bearing are used for both fan and water pump, airfoil hollow aluminum alloy axial flow fan, tilting structure design, small wind resistance, with Siemens,ABB, and other well-known motors.

|

Model |

Flow rate |

Fan data |

Spray pump |

Pipe dia. |

|

|

|

|

|

Power |

Blowing rate

M3/h |

Power

kW |

Flow rate |

In and out of the water tube (kW) |

Overflow |

Drain contamination

DN mm |

DN |

DN mm |

|

SL-30 |

30 |

1.5*2 |

19200*2 |

1.5 |

45 |

80 |

25 |

32 |

|

SL-40 |

40 |

1.5*2 |

25600*2 |

1.5 |

45 |

100 |

25 |

32 |

|

SL-50 |

50 |

2.2*2 |

32000*2 |

1.5 |

45 |

100 |

25 |

32 |

|

SL-65 |

65 |

2.2*2 |

41600*2 |

1.5 |

45 |

100 |

32 |

40 |

|

SL-80 |

80 |

3*2 |

51200*2 |

2.2 |

114 |

120 |

32 |

40 |

|

SL-100 |

100 |

4*2 |

64000*2 |

2.2 |

114 |

125 |

32 |

40 |

|

SL-125 |

125 |

5.5*2 |

80000*2 |

3.7 |

140 |

150 |

32 |

50 |

|

SL-150 |

150 |

7.5*2 |

96000*2 |

3.7 |

140 |

150 |

32 |

50 |

|

SL-175 |

175 |

7.5*2 |

112000*2 |

5.5 |

192 |

150 |

32 |

65 |

1. Matching with forging machine, annealing furnace,melting furnace and other production cooling.

2. Cooling of circulating water in various reactors and condensers in the chemical industry.

3. Cooling of the large motor, diesel engine, hydraulic station,etc.

4. Metal die casting mold, injection mold, and other large mold cooling.

5. Industrial solution cooling, such as quenching liquid, etc.

● Delivery time: in 15-30 working days.

● Warranty period: 12 months.

● Payment terms: 50% T/T, before shipment 100% T/T should be paid.

● Package: plywood cases.

● Port:Shanghai, Tianjin.

Water cooling tower system are equipment used for refrigeration and are widely used in industrial production and commercial fields. The main components are compressor, condenser, evaporator, expansion valve, water pump, fan and so on.

Get Started

The fan blade is the core component of the fan system, which directly affects the heat dissipation efficiency and system performance. Reasonable selection and regular maintenance can improve the efficiency and life of the chiller.

Get Started

The water pump is the core component of the chiller system, which is responsible for circulating cooling water to ensure the normal operation of the system. It mainly plays the role of water circulation and heat exchange.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible