1. The frequency range of ultrahigh frequency welding machine is 100-800KHZ, can according to customer’s request do the machine. To realize the steel, stainless steel, copper tube, aluminum tube welding.

2. Has an extremely strong resistance network pressure fluctuation ability.

3. Adopt the imported high power resonant capacitor to obtain the stable resonance frequency, effectively improve the product quality, and realize the stability of the welding process.

4. There is no 10,000-volt high frequency voltage in the machine, which is limited to avoid radiation, interference, discharge, ignition and other phenomena.

5. Small machine size, one body design, greatly saving the space.

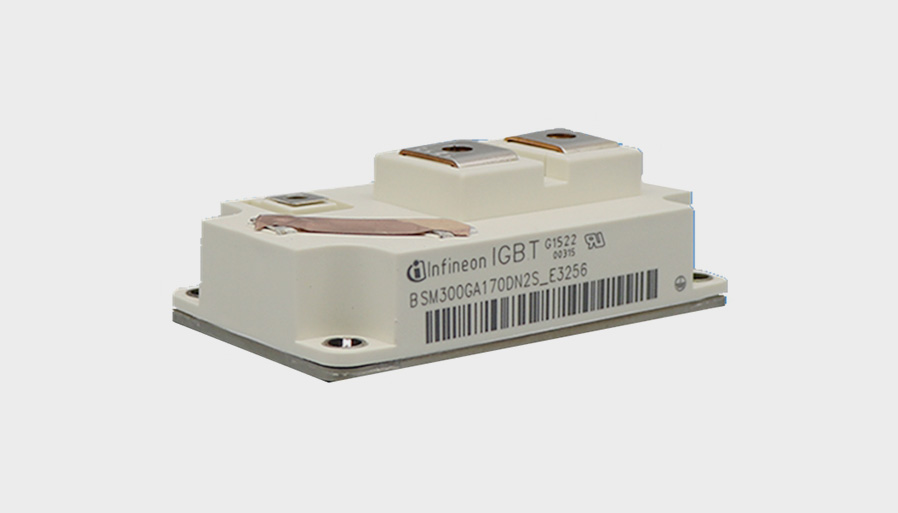

6. Real all solid IGBT power regulation technology, realize the 100-800KHZ/3-300KW induction tube welding machine products.

1. Adopt Siemens IGBT series circuit.

2. Automatic frequency tracking.

3. 100% duty cycle.

4. Perfect fault alarm functions.

5. High efficiency and energy-saving.

6. No high voltage, easy operation.

7. Can 24 hours continuous working.

1. To prevent electric shock, ensure that the electrical specifications of the chassis are reliably grounded.

2. Disassembly and installation of the inductor must be carried out after reheating is stopped.

3. Strictly implement the principle of connecting water first and then the power on, water shortage is strictly prohibited in the working process, and the quality and pressure of cooling water used in the equipment and induction coil must meet the requirement in Table 2. To avoid blocking the cooling pipes, if a water pump is used for water supply, install filter cooling water at the water pump inlet. The temperature should not be higher than 45℃, and the water flow should be 10T/H

4. The machine must be protected from sunlight, rain, humidity, and dust. When the device needs to be repaired or maintained, it must be repaired after the power if off.

5. Clean the machine with compressed air or a fan every week. The circuit board is cleaned with a brush and then blown clean.

6. Ordinary users should be used it every 4 months with special detergent to clean the machine once.When the machine frequently alarms water temperature, or observe the water flow at the outlet significantly reduced should be cleaned immediately.

7. The induction coil should be kept clean to prevent a short circuit between turns.

8. The ultrahigh frequency induction heating machine cannot use a single turn sensor. Otherwise, the device may be damaged due to too small inductive reactance. In special cases, please consult the manufacturer.

9. When replacing the induction coil, the induction coil connecting plate and the transformer contact surface should be sanded clean to maintain good conductivity.

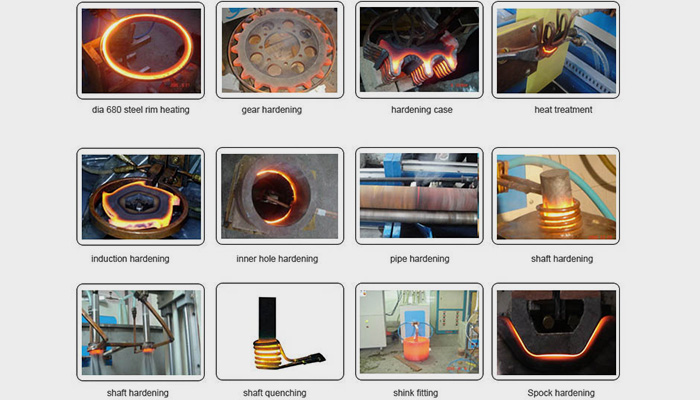

It can be used to heat almost any conductive material. It is the ideal induction heating equipment choice for brazing, heat shrinkage matching, quenching, curling, straightening, and other work.

We have worked in the heating industry for more than 20 years. We insist on doing every piece of machine well with our heart and strength our team with love and sincerity. No matter how the years change, we are always exploring the way of innovation, and strive to use advanced, to serve each of our users. No matter where you are, no matter at what time, when you need us, we are online 24 hours for your contact./p>

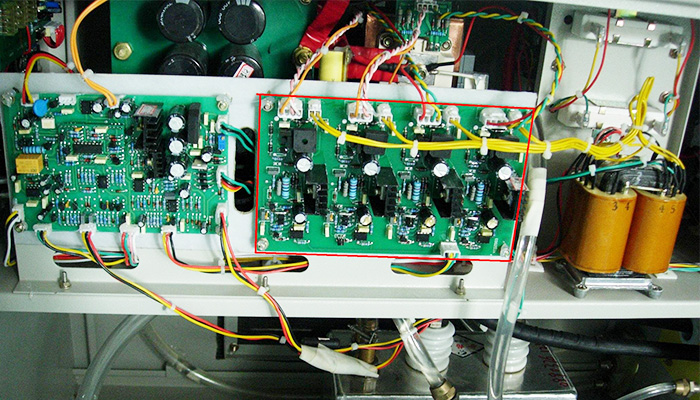

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible