Ultra high frequency induction heating machine adopts dual control variable current control technology. In this technology the power and the frequency can be separately controlled. With IGBT series resonance circuit and frequency automatic tracking technology, the accurate soft switch control of the inverting process is obtained. Machine output data is stable, the network pressure fluctuation ability is strong, working reliability is greatly improved, the machine works continuously with a 100% duty rate.

Also, the ultra high frequency series induction heating machine adopts the high frequency transformer secondary resonance circuit, the induction coil has a wide adaptability range. High frequency transformer low voltage, small volume, light weight, less loss, greatly reduce insulation, and ignition problems caused by high voltage, equipment reliability is also greatly improved.

|

Model |

Max. Input Power |

Frequency |

Memo |

|

FHC-10 |

10KW |

80-250KHZ |

One body |

|

FHC-20 |

20KW |

80-200KHZ |

Split Body |

|

FHC-40 |

40KW |

80-150KHZ |

Split Body |

|

FHC-70 |

70kW |

80-150KHZ |

Split Body |

|

FHC-120 |

120KW |

80-150KHZ |

|

|

FHC-160 |

160kW |

80-150KHZ |

|

|

FHC-250 |

250KW |

80-150KHZ |

|

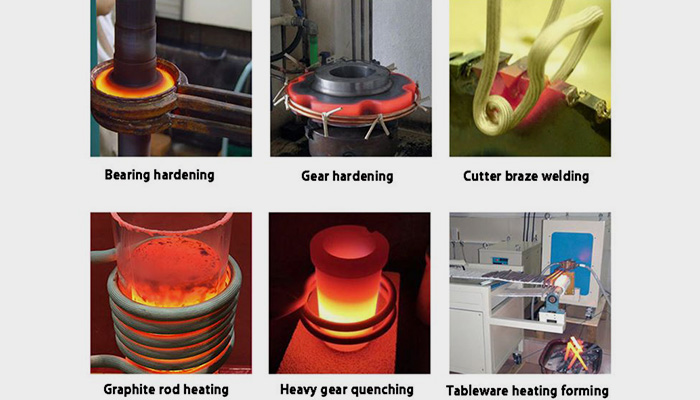

1. All kinds of gear and shaft heat treatment.

2. Carbon steel screws and stainless steel screw heated glue.

3. Magnetic suspension induction melting

4. Wire and pipes continuous heating annealing

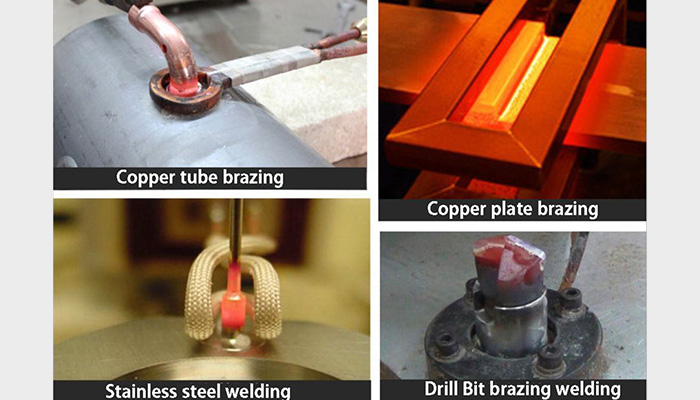

5. All kinds of metal material brazing welding

6. Tool welding, paper cutting knife, shoe blade quenching

7. Toy industry ( winding sheet metal tempering)

8. Welding annealing of spectacle frame and spare parts.

1. The cooling water should be clean and free of impurities. If the water quality is bad, a filter should be added to the water inlet.

2. A short circuit of the induction coil should be prevented during working.

3. The induction coil should be kept clean at all times, especially the multiple-turn induction coil to prevent a short circuit between turns.

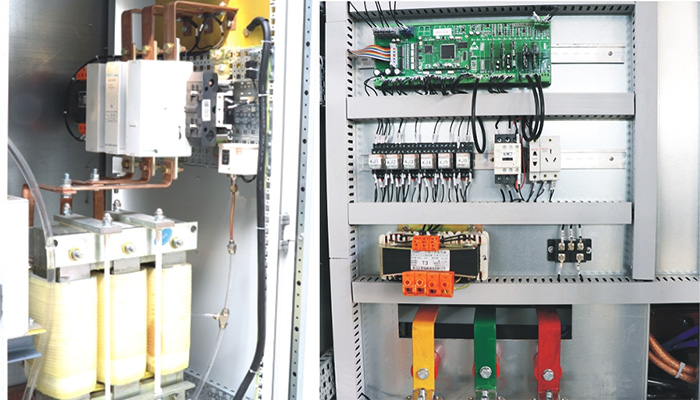

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible