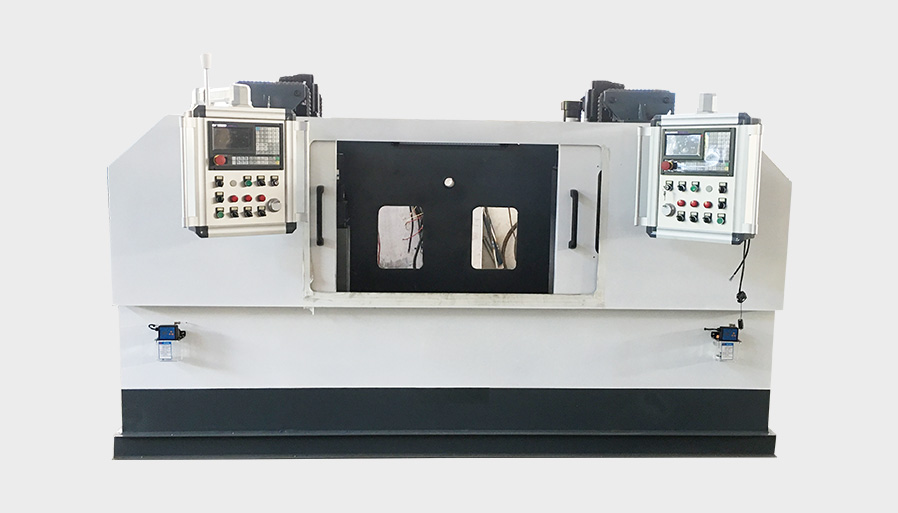

The shaft hardening machine series is mainly suitable for the light shaft, disc, small workpiece quenching jobs. By means of the workpiece moving. It can realize the continuous scanning quenching, piece wise scanning quenching, and piece wise overall quenching functions.

Using CNC system control and optional special parameter management monitoring and recording system, to achieve the quenching product process parameters and historical data query function.

The shaft quenching machine adopts a modular layout structure, has self-protection function.

|

Model |

FHGL500 |

FHGL1000 |

FHGL1200 |

FHGL1500 |

FHGL2500 |

|

workpiece length(mm) |

500 |

1000 |

1200 |

1500 |

2500 |

|

Max.rotating diameter(mm) |

Φ15-200 |

Φ30-400 |

Φ35-400 |

Φ50-400 |

Φ60-500 |

|

Workpiece weight(kg) |

50 |

150 |

150 |

300 |

500 |

|

Scanning length(mm) |

500 |

1000 |

1200 |

1500 |

2500 |

|

Transformer scanning speed (mm/s) |

0-50 |

||||

● This CNC quenching machine tool has the transformer rise and fall movement, advance, and retreat movement, spindle rotation quenching mode.

● Has the continuous hardening, simultaneous quenching, piece wise continuous quenching, and piece wise simultaneous quenching functions

● During the hardening period, the induction hardening machine power and induction heating coil moving speed can be changed as request.

● The machine is equipped with an induction heating quenching quality monitoring system, which can display, record, store, and query the induction heat treatment process parameters in real time.

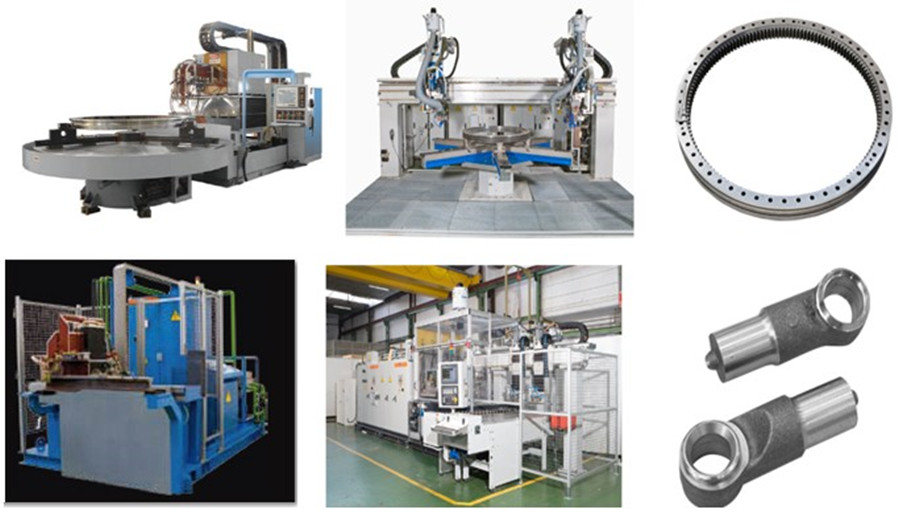

● This CNC quenching machine is mainly used in all kinds of shaft surface heating hardening jobs, like camshaft, crankshaft, small shafts, joint, and so on.

1. Factory direct delivery goods.

2. 24 hours of technical service

3. Free workpiece test

4. 20 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

Shaft hardening machine tool is a key equipment for metal heat treatment, mainly used for quenching, tempering and other processes.It includes machine tool bed,control system control panel,sensor and monitoring system temperature sensor, safety protection system overload protection,etc.

Get Started

The workpiece holding device of the quenching machine tool is the key component to ensure the stable position and attitude of the workpiece during the quenching process. Its functions are fixed workpiece, accurate positioning, fast loading and unloading. It is essential to ensure the stability and accuracy of the workpiece during the quenching process.

Get Started

The PLC automatic control display is the core part of the control system and is used to monitor and operate the quenching process. Its functions include real-time monitoring, operation control, fault alarm and data recording.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible