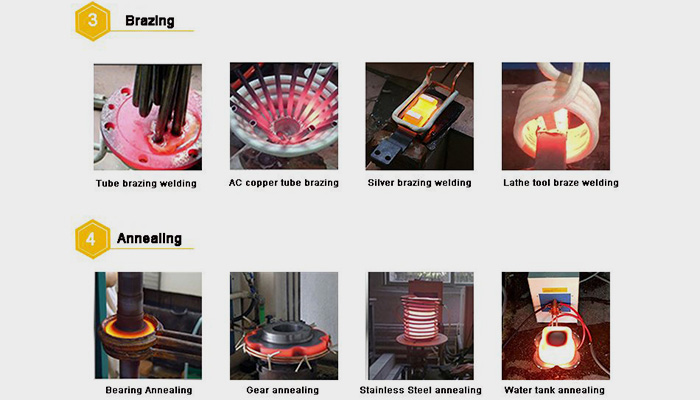

1. Air conditioning industry, online copper pipe brazing welding

2. Transformer copper joint welding

3. The connection between evaporator and compressor

4. Mainly used for the welding parts not move, the induction brazing coil moving.

1. The heating head is small with light weight, it is suitable for worker’s hand operation.

2. The heating head is durable, good quality.

3. There are one or more resonance capacitors inside the heating head, a simple cooling structure.

4. Energy saving, series circuit structure.

5. The portable induction heating machine is designed for special application ranges and its application ranges have limits.

The power range is 3-300KW, the customized frequency range is 5-300KHZ about the portable induction machine.

1. Main body

2. Induction head

3. Cables

4. Induction coil

The heated parts material magnetic induction performance varies greatly, the heating requirement are different. As per the different induction coil shapes and size, the machine need to adjusted to achieve good heating results. Then, we need to know the follow information.

1. The heated parts material and size, drawing is better.

2. The heating application and temperature, the heating time request.

1.Are you factory direct?

Yes, we are.

2.What is warranty?

All machine warranty period is 12 months.

3.What kind of packing?

All machines are packed with plywood case.

4.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

5.Can you customized the logo, color and others?

Yes, we can.

6. How do you control the quality?

We have a QC team comply with TQM to ensure the quality. We will take photos and shoot a video for you if you need.

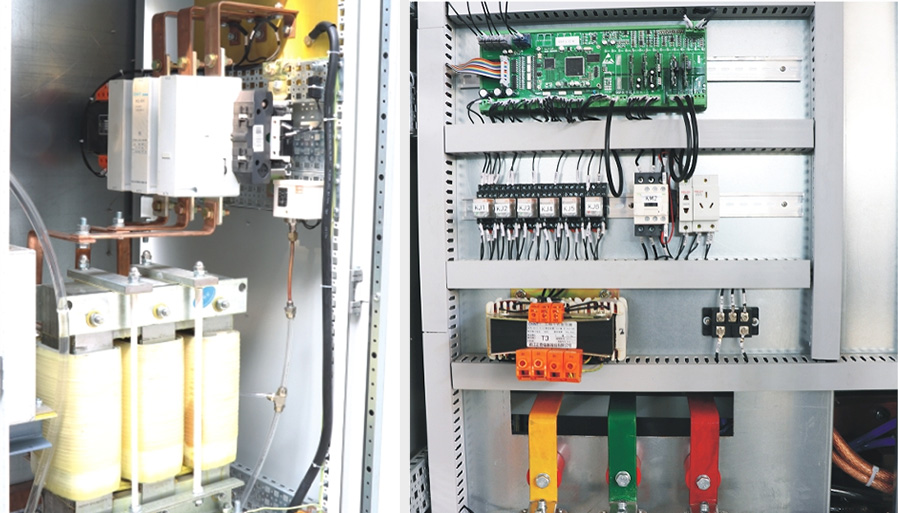

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Medium frequency pipe bender adopts medium frequency induction heating machine heating to bend the workpiece under the condition of local heating.

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible