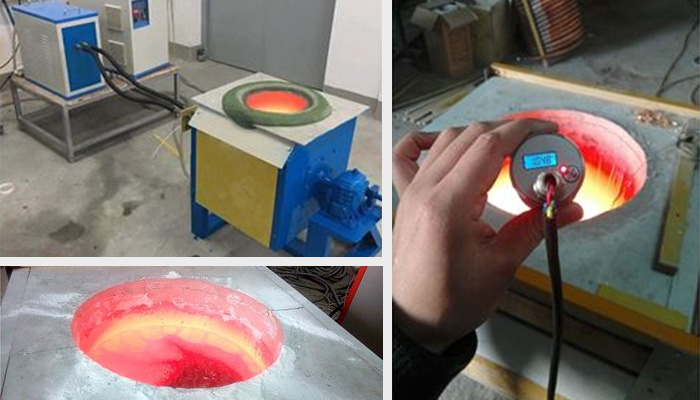

Induction melting furnace mainly consist of medium frequency power supply, melting furnace and compensation capacitor box. According to different application request, it may also include an infrared thermometer, temperature control, etc. It has three types of melting furnace: upside-down melting furnace, eject- out melting furnace, fixed melting furnace. Tipping melting furnaces can be divided into mechanical tipping furnaces, electric tipping furnace, an hydraulic tipping furnace.

1. 100% full load, 24 hours continuously working.

2. All-solid-state IGBT frequency conversion and function adjustment, realizing frequency conversion automatic tracking.

3. Over current, over voltage, over heat, lack of water, lack of phase.

4. High efficiency, low power consumption, simple operation and installation

|

Model |

Power |

Frequency |

Gold/silver/copper |

Stainless steel |

Alloy/Aluminum |

|

FHM-15 |

15KW |

1-20KHz |

10KG |

3KG |

3KG |

|

FHM-25 |

25KW |

1-20KHz |

20KG |

5KG |

5KG |

|

FHM-35 |

35KW |

1-20KHz |

30KG |

10KG |

10KG |

|

FHM-45 |

45KW |

1-20KHz |

50KG |

18KG |

18KG |

|

FHM-70 |

70KW |

1-20KHz |

100KG |

25KG |

25KG |

|

FHM-90 |

90KW |

1-20KHz |

120KG |

40KG |

40KG |

|

FHM-110 |

110KW |

1-20KHz |

150KG |

50KG |

50KG |

|

FHM-160 |

160KW |

1-20KHz |

250KG |

100KG |

100KG |

Medium frequency induction melting furnace is used in melting and heating of steel ,stainless steel, copper, gold,silver,etc.

Melting capacity range from 1KG to 200KG.The highest temperature is 1500-2000 degrees.

Melting is the process of converting metal into a liquid by applying high temperature to it.

● Mainly applicable to iron, steel, copper, aluminum, zinc, and various precious metals.Like the melting of gold and silver.

1. Factory direct delivery goods.

2. 24 hours of technical service online.

3. Free workpiece test and send test video to you.

4. 19 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

Induction heating melting furnace is a kind of equipment that uses electromagnetic induction principle to heat and melt metals. With its advantages of high efficiency, environmental protection and precise control, it is widely used in modern industry and is an important equipment for metal melting and heating.

Get Started

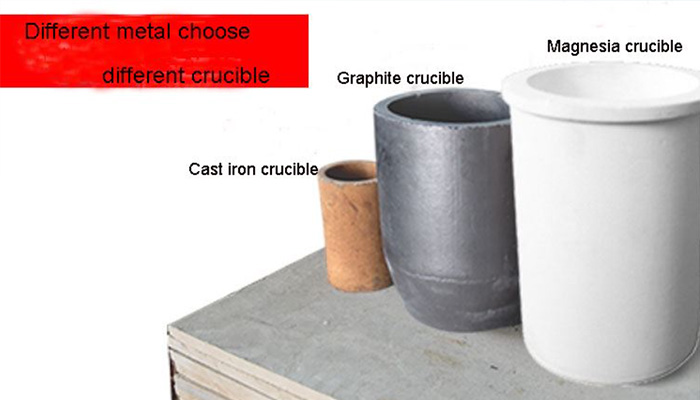

Crucible melting furnace is a device used to melt metal or other materials, the core component is the crucible, usually made of refractory material, can withstand high temperatures and chemical corrosion. The crucible melting furnace is an efficient and flexible device for many applications.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible