The new medium frequency induction heating machine is more intelligent can reach, less maintenance, much high efficiency, leading in domestic induction industry.

1. More intelligent: inverter power factor can reach 96%

2. More stable: the cabinet is well sealed, no failure all year, IGBT never burst.

3. Control precision can reach 0.1%, all loads can be automatically matched.

|

Model |

FHZ-25 |

FHZ-35 |

FHZ-45 |

FHZ-90 |

FHZ-110 |

FHZ-160 |

FHZ-300 |

|

Input power |

25KW |

35KW |

45KW |

90KW |

110KW |

160KW |

300KW |

|

Output voltage |

70-550V |

||||||

|

Input power supply |

Three phases 380V 50/60HZ |

||||||

|

Oscillating frequency |

100HZ-20KHZ, according to customer's heated parts to choose the best frequency range. |

||||||

|

Duty cycle |

100%, 24 hours of continuous working ability |

||||||

|

Memo |

Our standard medium frequency induction heater is three-phase 380V input voltage, suitable for 50 or 60HZ; Three-phase 400V, three-phase 415V, three-phase 440V, three-phase 460V, and three-phase 480V intermediate frequency power supply can be customized. Also can be customized three-phase 220V intermediate frequency power supply; |

||||||

Power range: 80-2000KW

Frequency range: 0.5-50KHZ

Power factor: >0.96

Control precision: 0.1%

Resonance mode: adjust voltage and power

Resonant mode: series, parallel , hybrid resonant

1. Bar and pipe online induction hardening and tempering system

2. Metal heat treatment (metal quenching, tempering, annealing,etc)

3. Bar and square bar online hot forging

4. Metal melting application

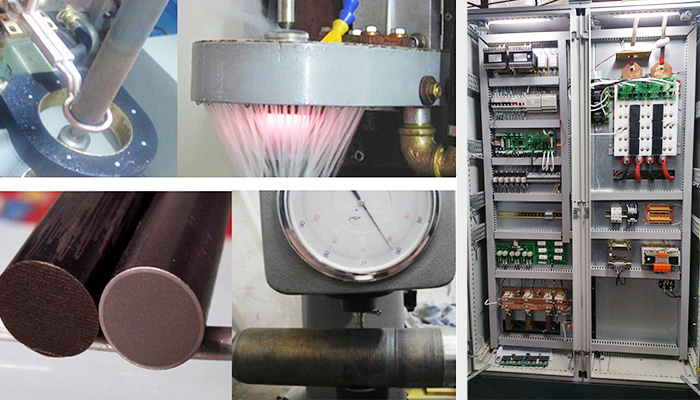

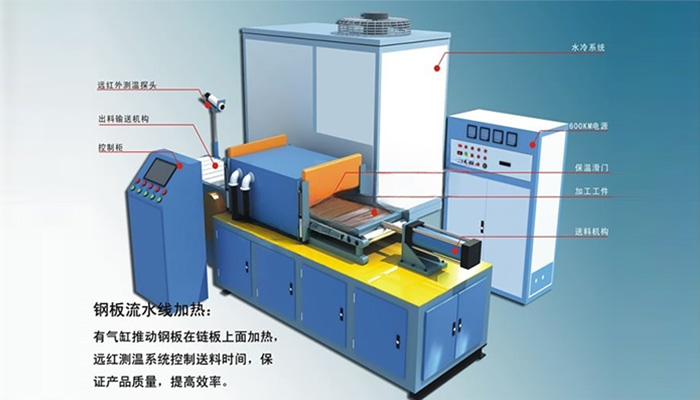

The internal structure of medium frequency induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The production workshop is standardized and clean, and the quality is strictly controlled.

Get Started

Induction surface hardening machine details : Power module provides high frequency alternating current, usually using IGBT or MOSFET and other power devices. Induction coil produces alternating magnetic field, shape and size according to the workpiece design. Control system adjust frequency, power and other parameters to achieve accurate control. Cooling system to prevent equipment overheating, commonly used water cooling or air cooling.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible