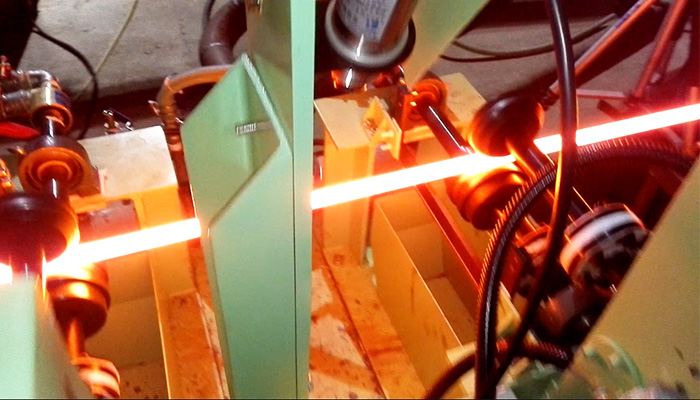

The medium frequency induction furnace’s frequency range is 1-20KHZ, power is from 15-500KW. Due to the lower frequency range, so the machine is used in the deep heating depth parts, melting, bar hot forging, pipe preheating, etc. Our machine could according to customer’s workpiece request, adopts suitable power and range to meet your need.

1. Small volume, light weight, can move freely.

2. 100% full load, can 24 hours continuously working

3. Lower power consumption, wide application case.

4. Prefect self-protection function

5. Adopt full solid state IGBT frequency conversion

|

Model |

Power |

Frequency |

Gold/silver/copper |

Stainless steel |

Alloy/Aluminum |

|

FHM-15 |

15KW |

1-20KHz |

10KG |

3KG |

3KG |

|

FHM-25 |

25KW |

1-20KHz |

20KG |

5KG |

5KG |

|

FHM-35 |

35KW |

1-20KHz |

30KG |

10KG |

10KG |

|

FHM-45 |

45KW |

1-20KHz |

50KG |

18KG |

18KG |

|

FHM-70 |

70KW |

1-20KHz |

100KG |

25KG |

25KG |

|

FHM-90 |

90KW |

1-20KHz |

120KG |

40KG |

40KG |

|

FHM-110 |

110KW |

1-20KHz |

150KG |

50KG |

50KG |

|

FHM-160 |

160KW |

1-20KHz |

250KG |

100KG |

100KG |

The machine has been widely used in the metal heat treatment fields, Can accept the free sample testing for your workpiece. At the same time ,like metal melting, brazing welding, quenching, annealing, tempering, etc.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

Medium frequency induction machine details : Power module provides high frequency alternating current, usually using IGBT or MOSFET and other power devices. Induction coil produces alternating magnetic field, shape and size according to the workpiece design. Control system adjust frequency, power and other parameters to achieve accurate control. Cooling system to prevent equipment overheating, commonly used water cooling or air cooling.

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible