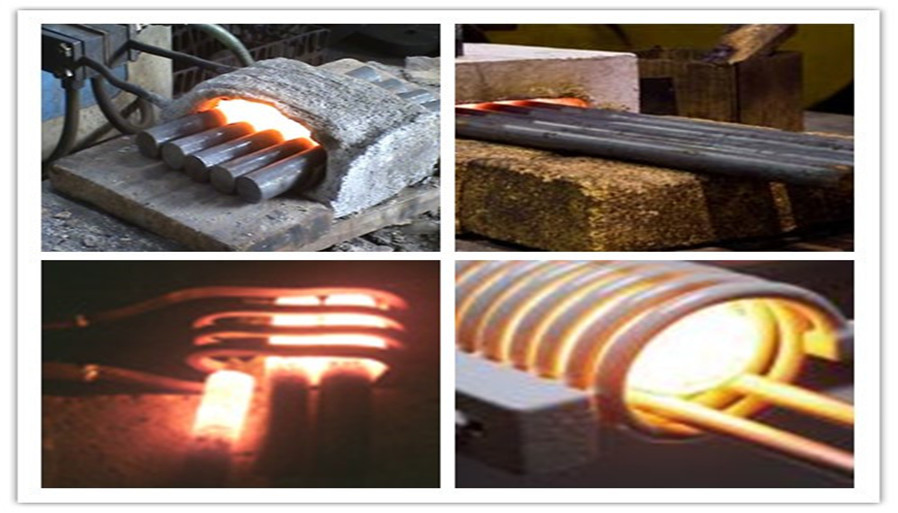

The principle of induction forging machine is electromagnetic induction. Non-contact heating, its heat in the workpiece itself, the heating rate is fast, so little oxidation, core meter temperature difference is very small, applied to round bar material, square material or other shapes of copper, iron, aluminum, alloy and other blank continuous diathermic workpiece, suitable for mass die forging production and precision forging. With forging, greatly increase the life of forging die, improve the quality of forging. Because the temperature can be well controlled, so easy to automation, good product consistency.

1. It has the perfect self-protection function,like over current, over heat, lack of water, lack of phase,etc.

2. No high voltage, stable function and easy to operate.

3. 100% full load design, can 24 hours continuous working.

4. Adopt infrared temperature measurement to realize automatic temperature control.

5. Adopt IGBT, KGBS variable frequency control technology.

6. It has the setting function of heating , heat preservation, and cooling for 3 periods. Low energy consumption, no pollution.

7. Uniform heating, high temperature control precision

|

|

FHT-40 |

FHT-100 |

FHT-150 |

FHT-250 |

FHT-300 |

|||

|

Support power requirement |

Input power |

50KVA |

120KVA |

180KVA |

300KVA |

350KVA |

||

|

Input wire |

25mm2 |

75mm2 |

100mm2 |

150mm2 |

200mm2 |

|||

|

Input on-off |

3*100A |

3*250A |

3*400A |

3*600A |

3*800A |

|||

|

Connect earth wire |

Not smaller than 6mm2 cooper wire |

|||||||

|

Support water requirement |

Water flux |

≥50L/min |

≥200L/min |

≥300L/min |

||||

|

Input water pressure |

0.2-0.4MPa |

|||||||

|

Input water temperature |

<40℃ |

|||||||

|

Measure (mm) |

length*width*high |

|

1220*650*800 |

1600*850*950 |

1650*850*1040 |

1880*850*980 |

||

1. Standard parts forging pressing

2. All kinds of billet bar forging

3. Steel tube end heating extension

4. Induction preheating

5. Motor rotor heating fitting

1. Keep air-cooled and water-cooled channels unimpeded at all times.

2. The adjustable components of the circuit board inside the equipment are closely related to the reliability an safety of the machine.

3. Water cooling is adopted in the main power devices inside the machine ,the temperature of cooling water is crucial to the cooling effect of the power devices.Please don’t turn off the cooling water during the gap time when the work stops. For the user whose load continuous rate is 100%, the temperature of cooling water should be lower than 40℃, and soft water is recommended.

1.Is it green for the environment?

Yes, our machine meets the environment protection requirement, low pollution, low consumption.

2.How to provide the professional induction annealing machine?

We have a strong technical team that will do many times tests according to your technical request. Until test is OK and then suggest suitable induction annealing machine to you.

3.What is your advantage compared to other company’s machine?

Our machine has excellent reliability 100% solid state design. We are manufacturer with a strong technical team for 19 years experiences and supply hundreds of induction heating technical schemes and machines.

4.How about the heating forging result?

The parts is heated uniformly, and temperature control precision is high.

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible