Magnetic induction heating machine is using the electromagnetic induction principle, so that to make the parts in the alternating magnetic field cutting magnetic field line, on the surface to produce the induction current, according to the alternating current skin effect, the surface of the parts is heated quickly in the eddy current form and then quenched abruptly. It occupies an important position in the field of heat treatment field, and this technology has been widely used in China and abroad.

1. Variable frequency adaptive: magnetic induction heating machine frequency range is 0.2-50KHZ, after process adjustment and load changed, the power frequency will automatically track to the load optimal resonant frequency.

2. Automatic power regulation: 10%-100 power level adjust freely

3. Power factor: more than 95%

4. 100% startup success rate

5. Can customized different voltage magnetic induction heating machine

Our company DSP digital magnetic induction heating machine all adopt German IGBT as its core component. Power range from 100-1000KW, with frequency range is 0.2-50KHZ, power factor bigger than 95%.

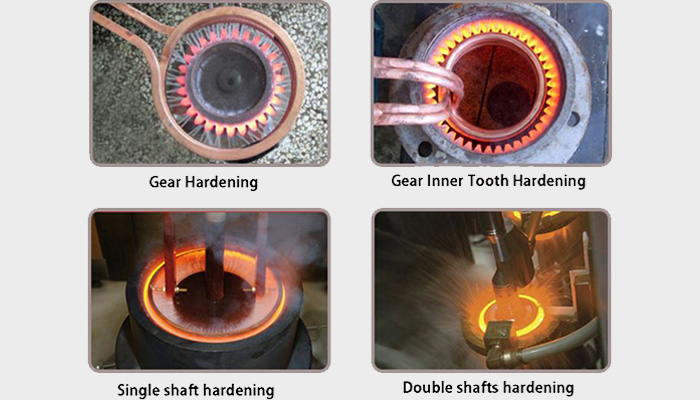

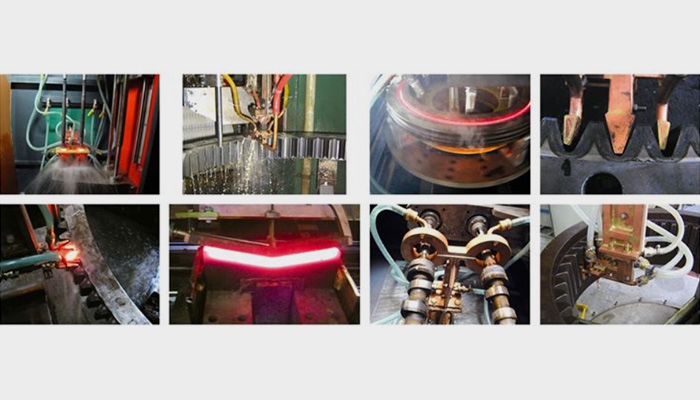

DSP digital magnetic induction heating machine is mainly used for hot forging, melting, gear hardening quenching, and tempering, and another heating process.

Machine has two main parameters, one is power, the other is frequency.

Power: decide heating speed, the bigger power, the faster the heating speed.

According to the parts weight and heating temperature and the request heating speed to choose the suitable machine power.

Frequency: The depth at which heat penetrates the workpiece depends on the frequency, and the higher the frequency, the shallower the heat penetrates.

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

Induction surface hardening machine details : Power module provides high frequency alternating current, usually using IGBT or MOSFET and other power devices. Induction coil produces alternating magnetic field, shape and size according to the workpiece design. Control system adjust frequency, power and other parameters to achieve accurate control. Cooling system to prevent equipment overheating, commonly used water cooling or air cooling.

Get Started

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Fill in the information and we will contact you as soon as possible