Induction hardening machine adopts the electromagnetic induction principle, make the parts in the alternating magnetic field cutting magnetic field line, on the surface to produce the current, according to the alternating current skin effect. The parts surface is heated quickly in the eddy current form and then quenched abruptly.

The workpiece surface hardening depth depends on the current frequency. So different frequency be selected to achieve different hardening layer depth. There are three categories as follow:

1. High frequency induction hardening machine: the frequency range is 200-300KHZ, the hardening depth is 1-2mm, normally used for small hardening depth, like gears and small shaft.

2. Medium frequency induction heating machine: the frequency range is 2.5-8 KHZ, the hardening depth is 2-10mm,used for the bigger shaft, small gear.

3. Power frequency induction heating: the frequency is 50HZ, the hardening depth can reach 10-15mm, suitable for roller, train wheels surface hardening.

1. The workpiece just heat a partial, so the deformation is small.

2. The parts heating time is short and the amount of surface oxidation and decarburization is lower.

3. Fast heating speed and high heating efficiency.

4. Facilitate mechanization and automation.

5. High surface hardness, impact toughness, wear resistance have been greatly improved.

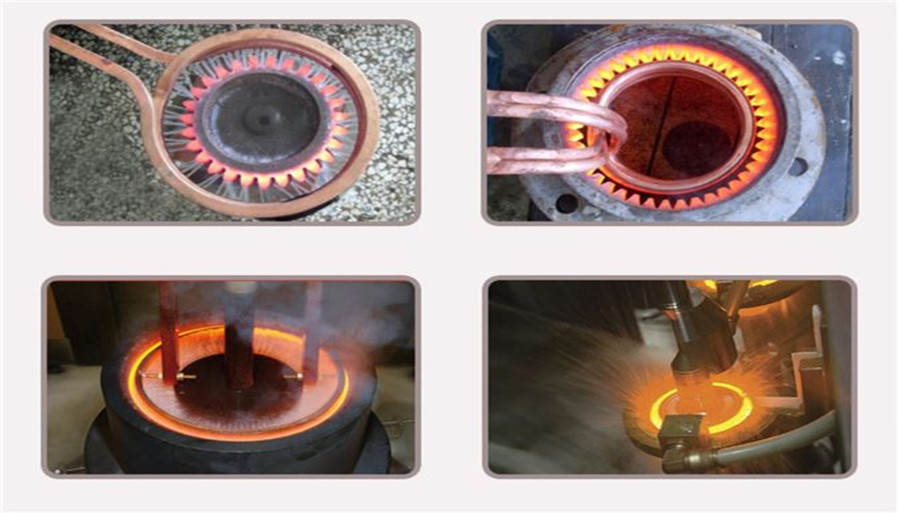

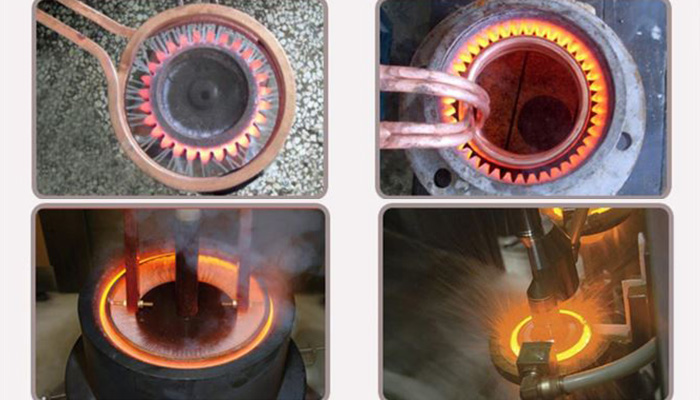

Induction surface hardening machines are mainly used for heating the metal workpiece, to let the metal material hardness changed to reach the hardening purpose.

The detailed application fields are as following:

1. All kinds of hardware tools, hand tools quenching hardening, like pliers quenching, spanner quenching, hammerhead quenching, ax quenching, screwdriver quenching, scissors quenching, etc.

2. All kinds of automobile and motorcycle parts quenching, like crankshaft, connecting rod, piston pin, sprocket, aluminum wheel valve, rocker shaft, drive axle, small shaft, fork hardening, etc.

During sales

The customer can send the workpiece to us, we can make suitable induction coil to heat your workpiece and checkout heating result.

After sales

1.We can provide technical support for all of our induction heating machine installation and debugging.

2.We will regularly follow up with users and provide heat treatment process improvement.

3.Our machine warranty period is one year, after that, we could continue to provide favorable machine accessory.

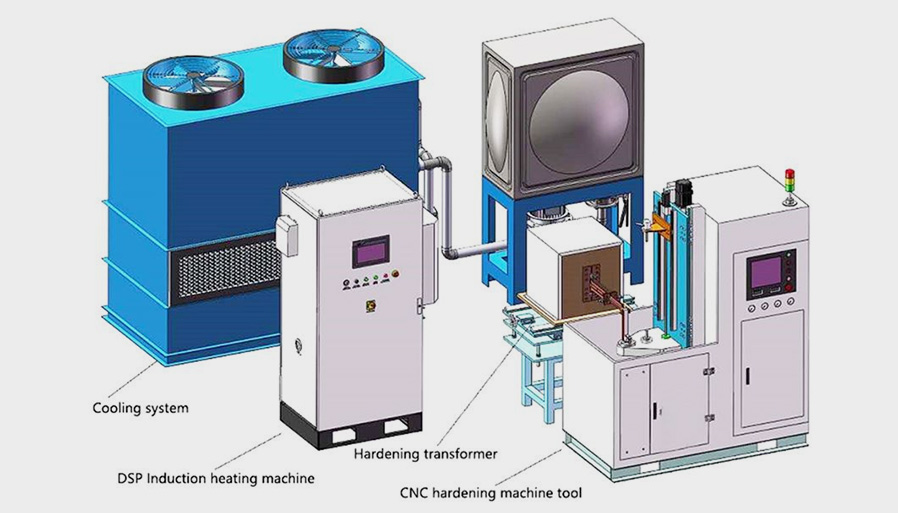

Induction surface hardening machine details : Power module provides high frequency alternating current, usually using IGBT or MOSFET and other power devices. Induction coil produces alternating magnetic field, shape and size according to the workpiece design. Control system adjust frequency, power and other parameters to achieve accurate control. Cooling system to prevent equipment overheating, commonly used water cooling or air cooling.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Main feature of IGBT

1).High voltage, high current: suitable for industrial motor drivers, inverters, etc.

2).High performance: Low on-off and switching loss, improve system efficiency.

3).Integrated protection: Built-in over current, overheat, short circuit and other protection functions to enhance reliability.

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

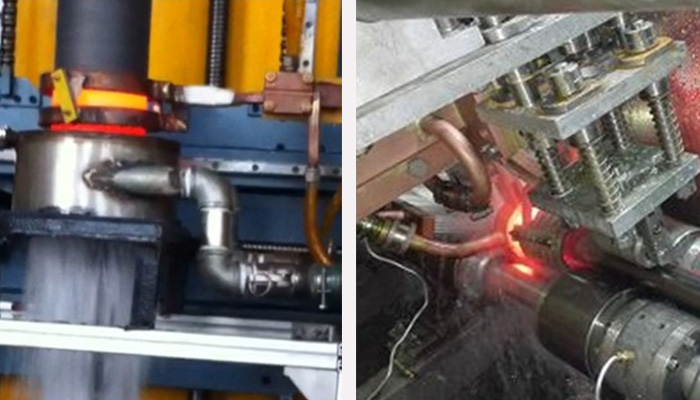

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Fill in the information and we will contact you as soon as possible