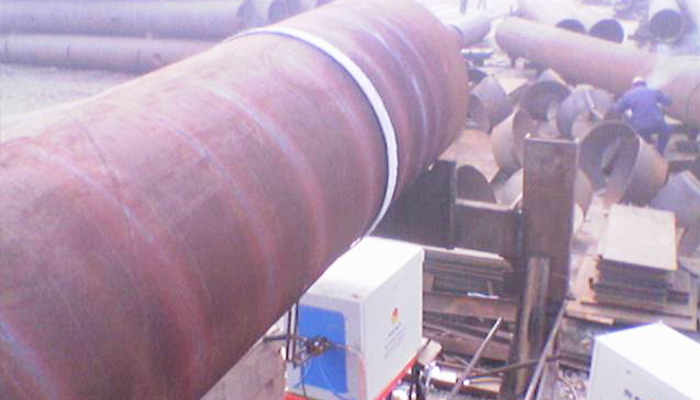

The process is to put an induction ring on the steel pipe part which is to be bent. The pipe head is jammed with a mechanical rotary arm, and the high density medium frequency current is fed into the induction ring to heat the steel pipe. When the steel pipe temperature reaches the plastic state, the steel pipe’s back end is pushed by a mechanical thrust to make the pipe bend. The process is as follow: heating, pushing, bending, cooling to complete the bending control.

High frequency induction pipe bending machine is mainly used for pipe annular induction heating. Make the steel pipe rapidly rise to required temperature (generally 800-1000℃).Output pulse is stable and energy-saving.

1. This process, a small radius and the thin wall 180 elbows with uniform wall thickness can be produced, with cannot by achieved by other pipe bending processes.

2. This process can avoid the uneven thickness phenomenon caused by the pressure of the pipe wall convex edge and concave edge.

3. If all kinds of technological parameters are designed reasonably, it can ensure that the wall thickness of each part of the pipe in the bending process is always unchanged. It is always equal to the wall thickness of the straight pipe before deformation.

4. The bending Angle of 45°,90° and 180° with the same Angle mandrel can be produced at one time with higher production efficiency.

5. Protection environment and no pollution.

This Induction Bending Equipment maximum bending pipe bending diameter is Φ 762 mm, wall thickness is 25 mm; The minimum pipe diameter is Φ 273 mm, wall thickness is 6 mm. The bending radius is 2.5m≤R≤20m, can process the maximum length of 14m. can bend 400 * 400, 300 * 300 square tube.

1.Are you factory direct?

Yes, we are.

2.What is warranty?

All machine warranty period is 12 months.

3.What kind of packing?

All machines are packed with plywood case.

4.What is your machine price?

We first know your heating material, heating speed and temperature, other request, and then suggest suitable machine models.

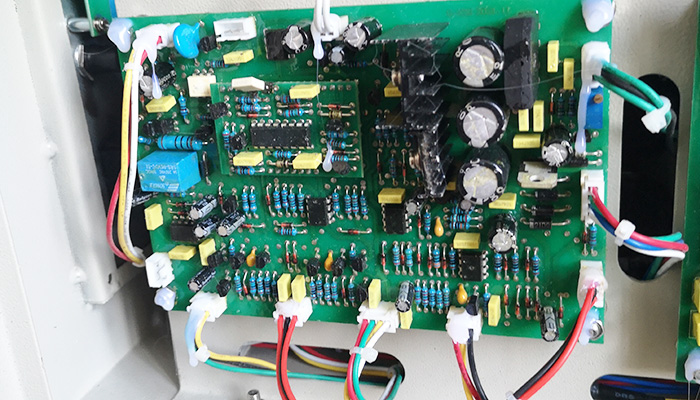

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The inlet and outlet of induction heating equipment is a key part of the cooling system to ensure effective heat dissipation during operation and prevent overheating damage. Understanding the function, location, connection mode, material, cooling water requirements, maintenance and safety precautions of the inlet and outlet helps to better use and maintain the induction heating equipment and ensure its long-term stable operation.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible