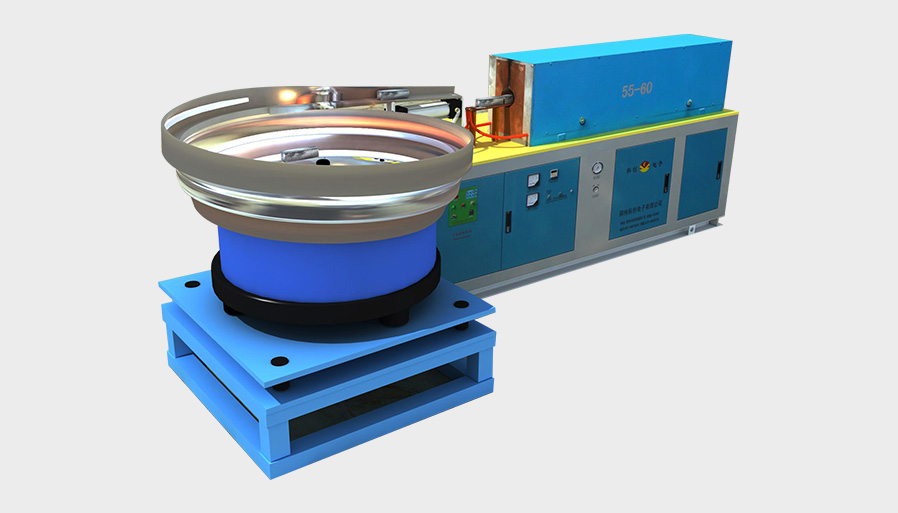

The main circuit adopt commute diode which direct commute all wave, its disturb is small to electric net wave. The filter circuit adopts combination filter form which direct current capacitance and high frequency capacitance, it avoids return back electric net of harmonic wave in inverse change circuit. The inverse change circuit is composed of IGBT, resonance capacitance and heating coil ,it is half bridge in series resonance circuit and don’t use match transformer. Direct heating workpiece in heating coil and electric efficiency is very high and save electric effort is clear. The originally bridge inverse change and induction coil is heating in forging after transformer matching. It waste 100 degree electric than half bridge heating. Due to heating coil is long enough, if machine efficiency is little high, workpiece heating is also uniformity. This is help solution “ black-heart” problem in big diameter workpiece. Other, we increase electric area from main circuit to heating coil, cooper heating wastage drop to lowest. At the same time, cooler water is expedite and not easily happen jam to damage accessory. Control circuit and bridge machine aren’t change, guarantee and installation in the same basically.

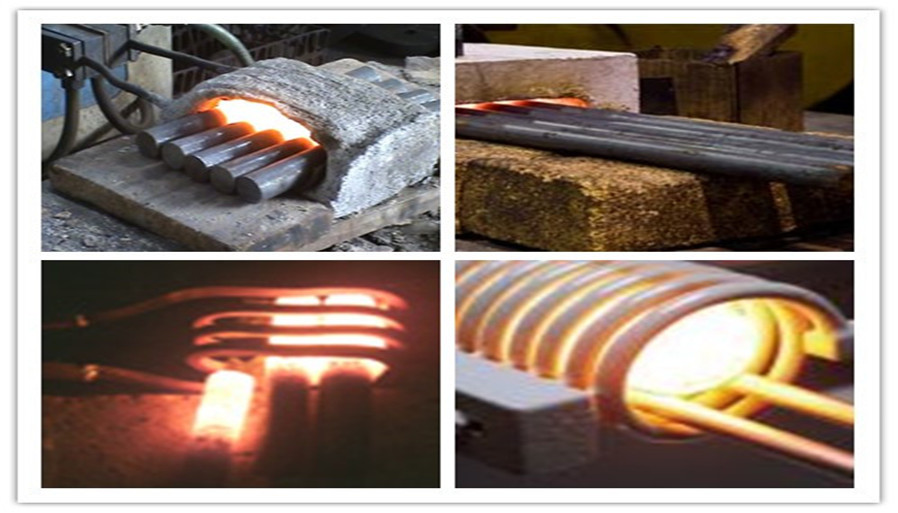

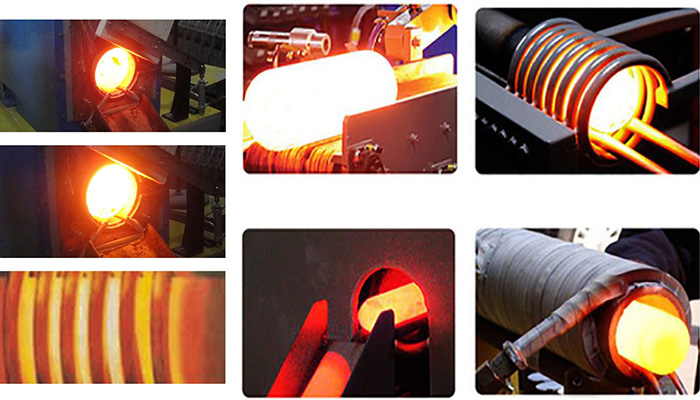

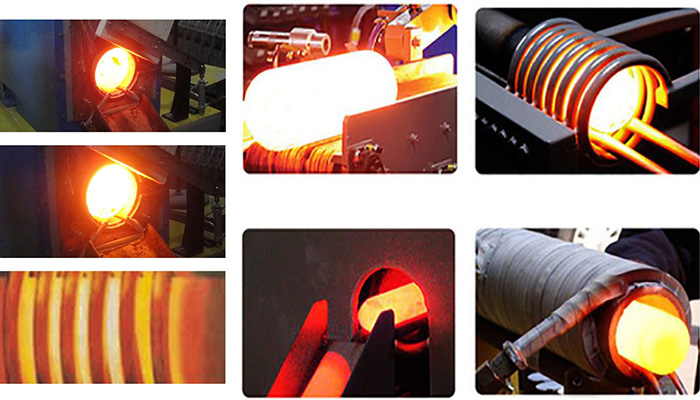

1. Widely used in metal forging applications, such as the round bar, square billet.etc.

2. High heating speed, high production efficiency, less oxidation

3. Lower energy consumption, no pollution, uniform heating

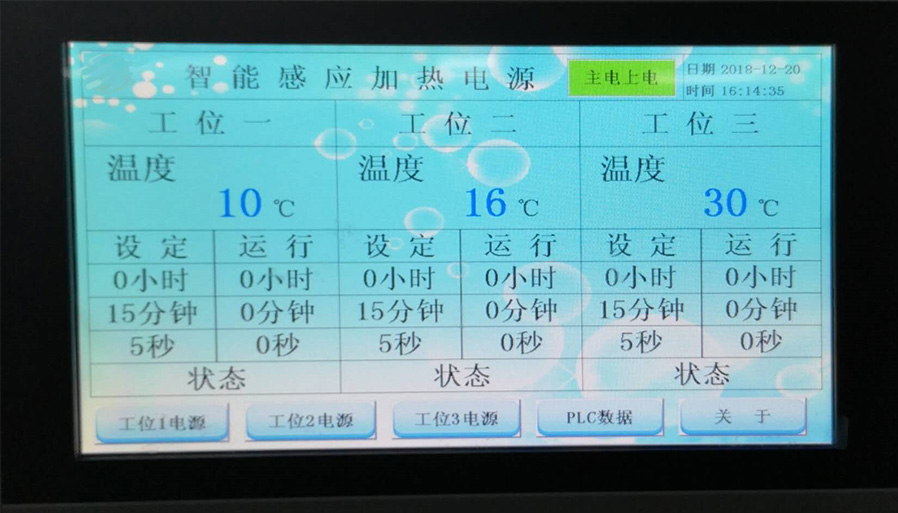

4. PLC control, touch screen man-machine interface, flexible operation, high reliability, easy to upgrade.

1. Machine layout, foundation diagram, water circuit diagram.

2. Electrical schematic diagram and external wiring diagram

3. Control electrical schematic diagram

4. Machine operation and maintenance instructions

5. Main outsourcing parts, parts specifications

6. Machine inspection certificate, ex-factory packing list.

|

Type |

FHT-40 |

FHT-100 |

FHT-150 |

FHT-250 |

FHT-300 |

|

Input voltage |

~3x380V±10% 50HZ |

|

|

||

|

Input power |

40 |

100 |

150 |

250 |

300 |

|

Frequency |

10±2,20±5 |

10±2 |

10±2,6±1 |

6±1,4±1 |

6±1,3±1 |

|

Output(kg/min) |

1-2 |

3-5 |

5-7.5 |

8-12 |

12-14 |

|

Diameter |

≤25 |

≤40 |

≤60 |

≤100 |

≤150 |

|

Flux( L/min) |

50 |

200 |

200 |

200 |

300 |

|

Measure(mm) |

|

1220*685*800 |

1600*850*950 |

1650*850*1040 |

1880*850*980 |

|

Weight ( kg) |

|

|

|

|

|

|

Type |

FHT-40 |

FHT-100 |

FHT-150 |

FHT-250 |

FHT-300 |

|

Input voltage |

~3x380V±10% 50HZ |

|

|

||

|

Input power |

40 |

100 |

150 |

250 |

300 |

|

Frequency |

10±2,20±5 |

10±2 |

10±2,6±1 |

6±1,4±1 |

6±1,3±1 |

|

Output(kg/min) |

1-2 |

3-5 |

5-7.5 |

8-12 |

12-14 |

|

Diameter |

≤25 |

≤40 |

≤60 |

≤100 |

≤150 |

|

Flux( L/min) |

50 |

200 |

200 |

200 |

300 |

|

Measure(mm) |

|

1220*685*800 |

1600*850*950 |

1650*850*1040 |

1880*850*980 |

|

Weight ( kg) |

|

|

|

|

|

Note: Every type machine parallelism a inverse change frequency. If it has two inverse change frequency, choose one random according to workpiece requirement. Output is heating weight which heat round steel to 900-1200℃.

Common heating coil collocate

|

Coil type |

D40 |

D70 |

D90 |

D110 |

D150 |

D200 |

|

Diameter(mm) |

14-19 |

20-32 |

34-50 |

50-65 |

85-100 |

120-150 |

Note: The whole set machine leaves factory ,we have selected one heat coil collocate which accomplish workpiece heating in establish range. If consumer workpiece type many, we could support other 2-3 unit heating coil In precondition of machine total power satisfy workpiece requirement. If you have other demand, we could design matching heating coil.

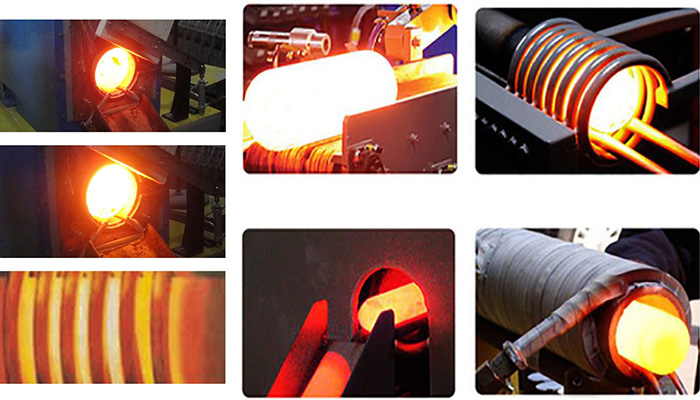

Hot forging is mainly to heat the workpiece to a certain temperature (according to the different material heating temperature is different), through the punch, forging, or other forms of the workpiece into other shapes.

For example: watch case, table blank, mold accessories, crafts, standard parts, fasteners, mechanical parts processing, copper lock, drill tool hot extrusion, and so on.

1. Keep air-cooled and water-cooled channels unimpeded at all times.

2. The adjustable components of the circuit board inside the equipment are closely related to the reliability an safety of the machine.

3. Water cooling is adopted in the main power devices inside the machine ,the temperature of cooling water is crucial to the cooling effect of the power devices.Please don’t turn off the cooling water during the gap time when the work stops. For the user whose load continuous rate is 100%, the temperature of cooling water should be lower than 40℃, and soft water is recommended.

1. Correct maintenance can ensure the machine has good working performance and long service life.

2. Water cooling is extremely important for induction heating machine, Poor water quality will lead to rust and scaling inside the machine and blockage of pipelines, which will directly lead to machine damage and failure to work normally.

3. Recommended cooling water: distilled water-softened water-purified water-filtered tap water.

1.What’s your circuit mode?

Our circuit mode are IGBT and KGPS series and parallel.

2.If our machine come out fault, how could you help us to solve problem?

We can adopt video to guide you to check, and then in time send the spare parts to customer for changing to ensure the machine could work normally.

3.Is it green for the environment?

Yes, our machine meets the environment protection requirement, low pollution, low consumption.

4.How to provide the professional induction annealing machine?

We have a strong technical team that will do many times tests according to your technical request. Until test is OK and then suggest suitable induction annealing machine to you.

The display screen is an important part of the induction heat treatment heating equipment, through high definition, touch control, real-time monitoring and other functions, improve the operating efficiency of the equipment and user experience.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible