1. Fast brazing speed

2. High yield rate of the finished products, unified welding performance

3. Easy to operate

4. Greatly reduce the processing cost of each workpiece, so achieve the maximum benefit.

5. Each time can braze multi-products, the appearance of the brazed part is perfect.

6. Support customized induction welding system for different parts and requests.

|

Item |

Contents |

Item |

Contents |

|

Input voltage |

380V, 1 zero line |

Chip speed |

72MHz |

|

Frequency |

50HZ |

Heating current |

5 sections ( reach 32) |

|

Heating time setting |

0.1S |

|

|

|

Rated power |

15-60KVA |

Max. power |

18-72KVA |

|

Air switch current level |

32-120A |

Working current display |

display |

|

Rated output power |

12-60kW |

Alarm interface |

Over current,etc |

|

Max. Output power |

18-70KW |

Communication interface |

DB-9 and 4-core aviation plug |

|

Main control chip |

ARM STM32 |

Water flow |

10L/min |

|

Max.cooling water Temperature |

40℃ |

Environment temperature |

+0.5℃---50℃ |

|

Cooling water pressure min./max |

4/6 bar |

Cooling water quality PH value |

7.0-9.0 |

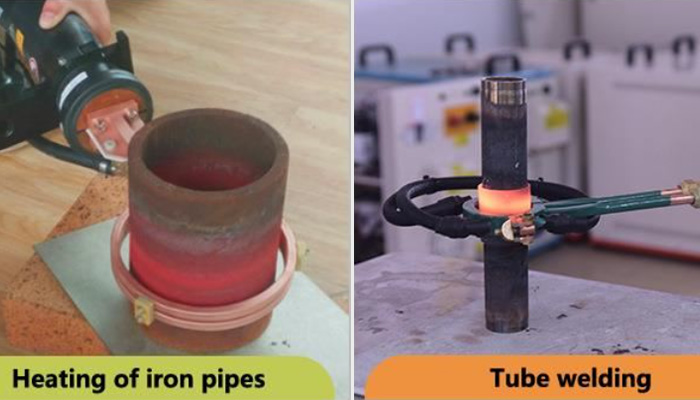

It is mainly used for aluminum tubes, copper tube, pipe joint, air conditioner, valves, home appliance metal parts brazing welding jobs.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get Started

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible