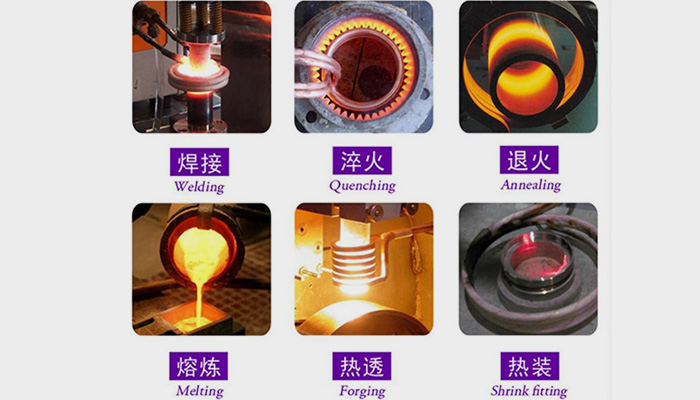

For heat treatment: In combination with the shape of the workpiece, quenching mode, quenching hardness, quenching layer requirement, and material, technical personnel can be consulted.±

For forging : Choose the right power according to the production efficiency, the higher the power, the faster the speed.

For brazing : the larger the welding volume is ,the lower the frequency is .

For melting: It depends on the furnace and production efficiency.

1. Fast heating speed

2. Wide application fields.

3. Easy installation

4. Convenient to operate

5. Less power consumption

6. Adopt the German original Siemens IGBT power module

7. Most of the machine problems are caused by substandard water quality. The internal circulating water system is one of the supporting equipment specially designed by us to improve the stability of intermediate frequency power supply.

|

Technical parameters |

FHG-50 |

FHG-100 |

FHG-160 |

FHG-200 |

|

Output power (KW) |

50 |

100 |

160 |

200 |

|

Output frequency(Khz) |

50-200 |

50-200 |

50-200 |

50-200 |

|

Input voltage(V) |

380V |

380V |

380V |

380V |

|

Input frequency(Hz) |

50/60 |

50/60 |

50/60 |

50/60 |

|

Water flow(l/min) |

30 |

40 |

50 |

60 |

|

Cooling temperature(℃) |

<35 |

<35 |

<35 |

<35 |

|

Working temperature(℃) |

0-40 |

0-40 |

0-40 |

0-40 |

Induction quenching machine is mainly used for the gear, shaft, guideway, roller, camshaft, crankshaft hardening jobs.

1. Warranty period is 12 months.

2. We have strong sales team. Before sales service, our team can according to user’s requests do the related technical proposal for our customer. After sales, our team will provide machine installation and technical training.

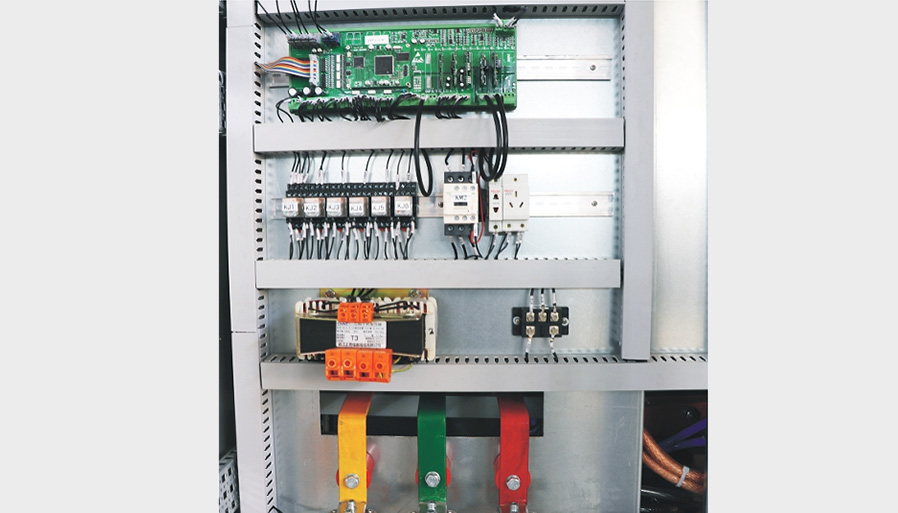

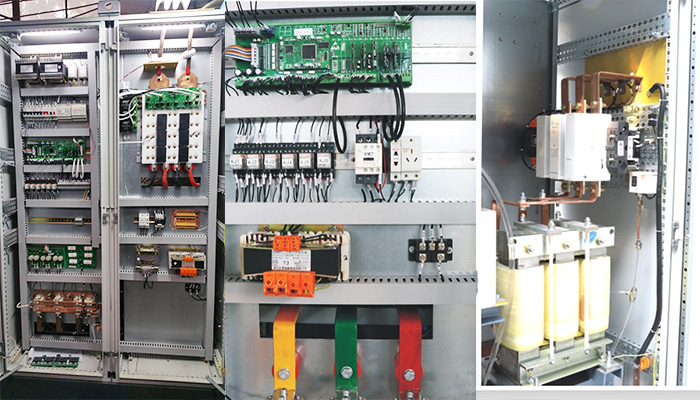

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get Started

The chassis circuit board is the core part of the induction heating equipment, which is responsible for integrating and controlling the work of each component.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Medium frequency pipe bender adopts medium frequency induction heating machine heating to bend the workpiece under the condition of local heating.

Fill in the information and we will contact you as soon as possible