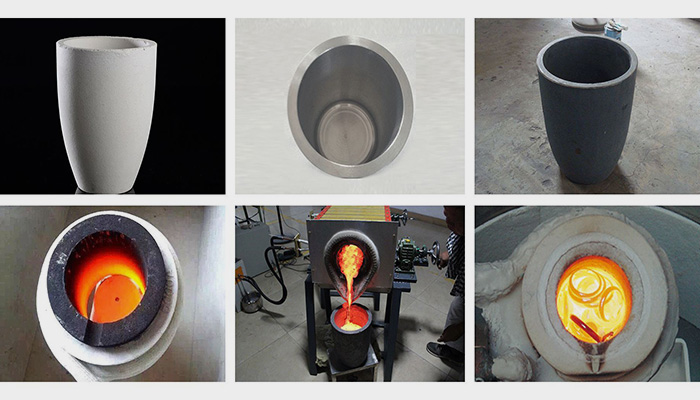

The principle of induction melting furnace is electromagnetic induction, and its heat is generated by the metal material itself, so this heating method has a fast heating speed, little metal oxidation, and high heating efficiency. It is convenient to adjust the current and power of the medium and high-frequency induction power supply equipment. The temperature can be accurately controlled through the temperature control system, so that the metal materials can be heated evenly and the product can be repeated accurately. An induction melting machine can melt iron, aluminum, stainless steel, copper, platinum, gold, silver, and alloy.

1. Can stable work 24 hours.

2. 100% success startup.

3. High melting efficiency, 10-20 minutes a furnace.

4. Adopts modular design, easy to maintenance and operate

5. Save energy, protect environment

6. Perfect self-protection function, such as over heat, over current, etc

7. Convenient to change varieties, furnace body can be electric dumping, easy to pour liquid, suitable for casting.

|

Melting power |

Aluminium alloy |

Gold, silver, copper |

Stainless steel |

|

15KW |

3KG |

10KG |

4KG |

|

25KW |

6KG |

20KG |

8KG |

|

35KW |

12KG |

40KG |

12KG |

|

45KW |

21KG |

70KG |

18KG |

|

70KW |

30KG |

100KG |

28KG |

|

90KW |

40KG |

120KG |

45KG |

|

110KW |

50KG |

150KG |

6KG |

|

160KW |

75KG |

250KG |

100KG |

According to the machine recommended in the table above, the maximum melting time from the cold furnace is 50-60 minutes. As the furnace temperature has increased. The second melting time is 20-30 minutes.

It is used for melting precious metals, such as gold, silver, copper, iron, steel, stainless steel, aluminum, and other metal melting and temperature raising. It is a university laboratory, research institute, jewelry processing ,casting processing and other industries. We have rich application experience and can customize products according to your request.

1. Factory direct delivery goods.

2. 24 hours of technical service

3. Free workpiece test

4. 20 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

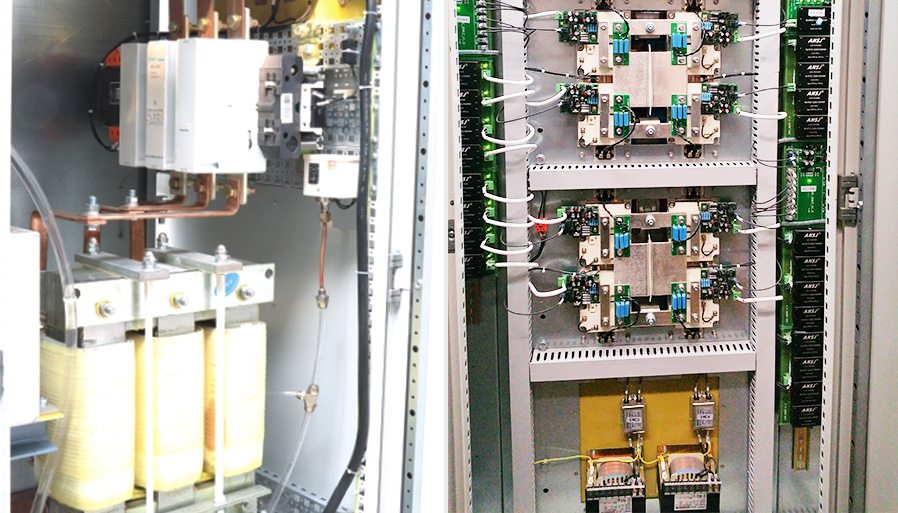

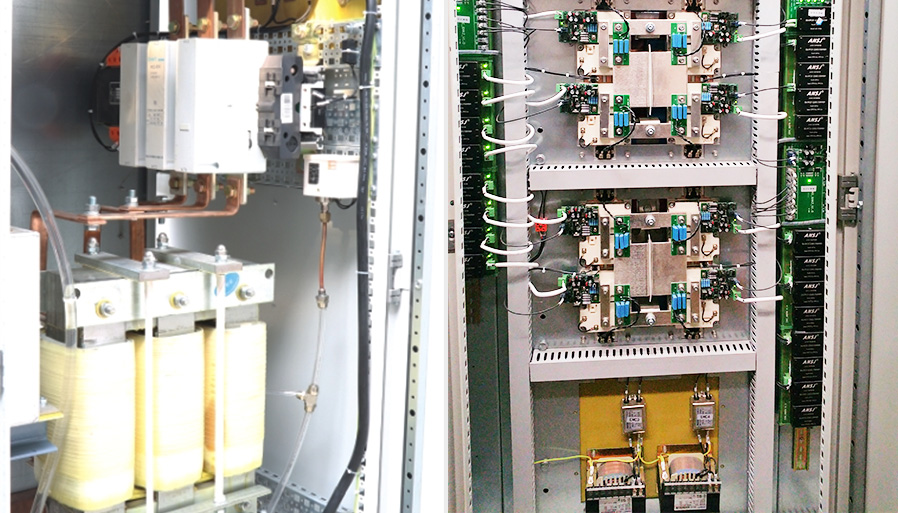

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The internal structure of induction heating equipment is complex, including power module, induction coil, control system, cooling system, protection circuit, transformer, capacitor, connection cable, housing and rack and other key components. These components work together to achieve an efficient and precise heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: Conveying straight pipe

Product specifications: φ120×500-3500mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible