● The heating head is small with lightweight, it is suitable for workers’ handheld operation jobs.

● The heating head is durable, good quality, and easy to maintain.

● There are one or more resonance capacitors inside the heating head, a simple cooling structure.

● The portable induction heating machine is designed for special application ranges and its application ranges have some limits.

1. The flexible induction heater cable length can be customized.

2. The connection water cable is soft and with a durable long lifetime design.

3. Easy to realize the automatic brazing welding

4. Safety operation ,can work in the vacuum and gas protection conditions.

5. DSP digital control

6. Ultrahigh precision control

7. Seal protection

Power range: 5-300KW

Frequency range: 0.1-100KHZ

Power factor: more than 0.96

Resonance mode: series resonance

Power adjustment mode: soft switch pulse width modulation

Control precision:0.1%

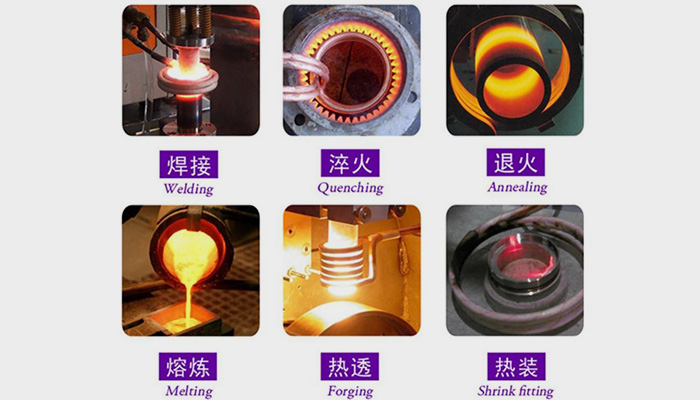

The flexible induction heater is mostly used in the brazing welding fields.It is with the handheld induction head.

The flexible induction heater is mostly used in the motor maker factory, transformer factory, air condition refrigerator compressor, etc. Suitable for the copper, aluminum brazing welding projects.

1. We are the top induction heating machine supplier, no agents.

2. We have strong technical team for 19 years product experience and make sure the delivery time.

3. The main components are mainly the international brand, stable and safe.

4. We have professional after-sales teams, and solve the customer problem in time.

Handheld induction coil is easy to operate and flexible, used in workpiece part welding.

Get Started

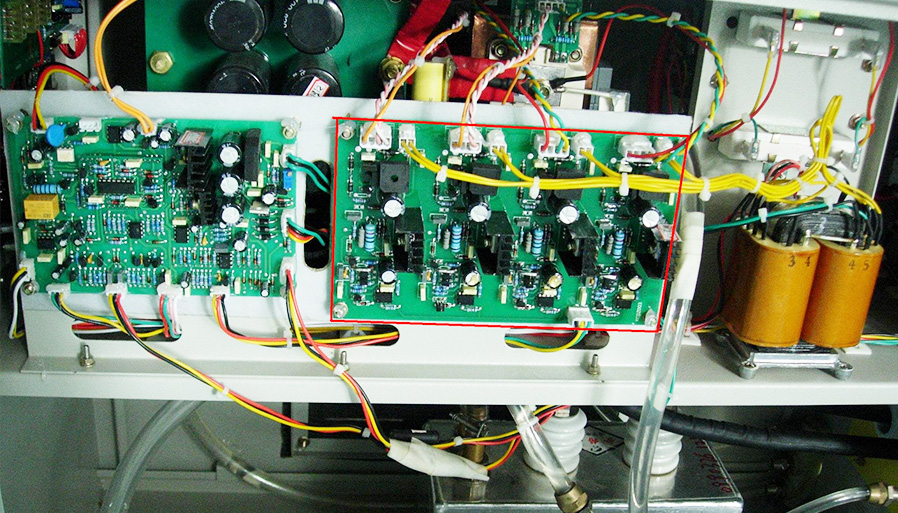

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get Started

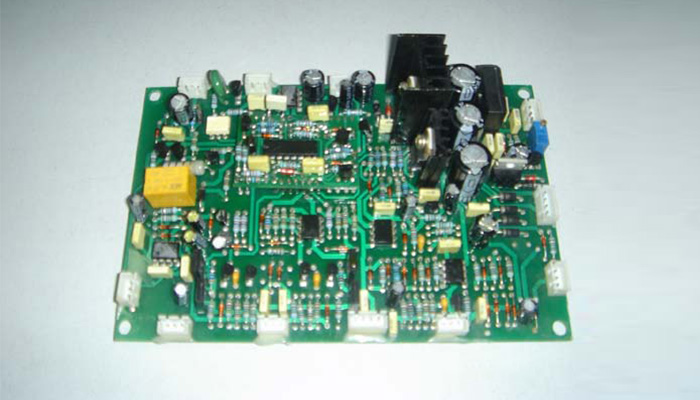

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Medium frequency pipe bender adopts medium frequency induction heating machine heating to bend the workpiece under the condition of local heating.

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible