The laser light of the laser is transmitted by the optical fiber to the hand-held laser welding torch and than focused on the surface of the workpiece to be welded. After being absorbed by the weld, it is converted into heat energy to melt the weld material or the welding wire. A high-quality weld bead is formed through the protection of inert gas, so that the two workpiece are firmly welded together. The water flow of the chiller keeps the temperature of the laser and the hand-held welding head down to a constant temperature, thereby continuously protecting important parts.

1. Both cutting and welding

2. Welding thickness up to 0.5-10mm

3. The operation is easy to learn, doesn’t require professional welders, and the welding speed is fast.

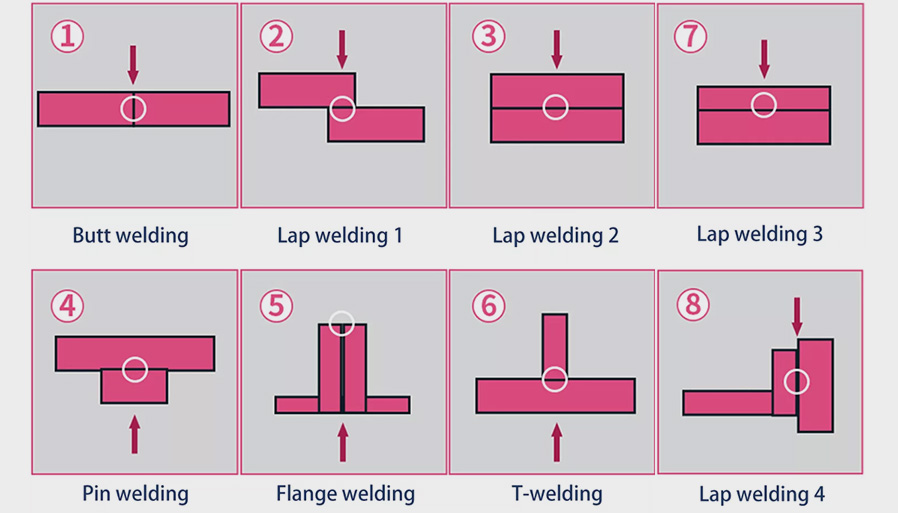

4. The deformation of the workpiece is small, suitable for a variety of welding processes.

5. Good heat dissipation, easy to maintenance, and flexible movement

6. Double water circuit design, good stability of cooling effect.

7. The welding wire nozzle adopts anti-deflection design, which effectively solves the situation that the welding quality is unqualified due to the deviation of the welding wire during use.

8. Equipped with internationally famous brand laser, optional .

9. Equipped with a step-by-step wire feeder dedicated to laser welding, the drive is strong and powerful, avoiding wire-feeding jams and unstable speeds.

|

Material |

Thickness power |

Welding penetration max. Material |

Welding maximum material |

|

Stainless steel |

1000W |

3mm |

4mm |

|

1500W |

4mm |

5mm |

|

|

2000W |

5mm |

6mm |

|

|

Gal vanized steel |

1000W |

2mm |

3mm |

|

1500W |

3mm |

5mm |

|

|

2000W |

3mm |

6mm |

|

|

Iron |

1000W |

3mm |

5mm |

|

1500W |

4mm |

6mm |

|

|

2000W |

4mm |

6mm |

|

|

Aluminum |

1000W |

1mm |

2mm |

|

1500W |

2mm |

3mm |

|

|

2000W |

3mm |

4mm |

|

|

Copper |

1000W |

1mm |

2mm |

|

1500W |

2mm |

2mm |

|

|

2000W |

2mm |

3mm |

1. Load material: Operators only need to place the product in the appropriate position to carry out automatic welding. There is no need to manually adjust the machine parameters. The product parameters are well set, the corresponding product parameters can be called out when working.

2. Automatic unloading material with robot: the turntable automatic induction heating machine unloading material is divided into two kinds: one is automatic unloading, you can choose robot unloading or automatic device. Self-unloading material is suitable for assembly line operation. Using robot unload material can be flexible docking next station. The other is an artificial material collection,in the case of simple welding products, loading an unloading can be performed by the same operator.

3. High yield: no matter what products you do , we can design a full range of welding programs for you need.

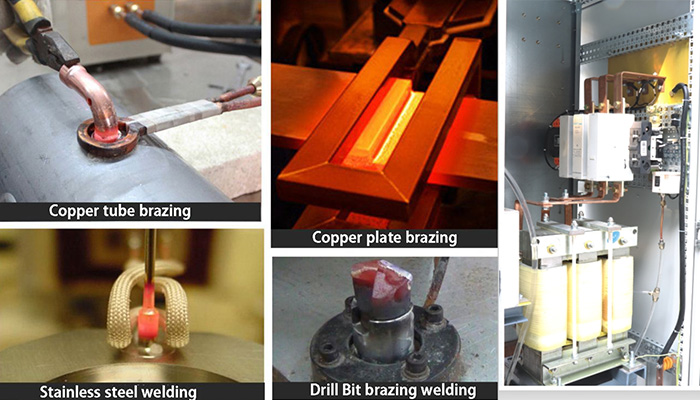

4. High quality: Induction brazing of pipe joints can reach the deepest penetration. Brazing time is short and the surface joint is less oxidized.

5. Save energy, safety

6. Stability and reliability

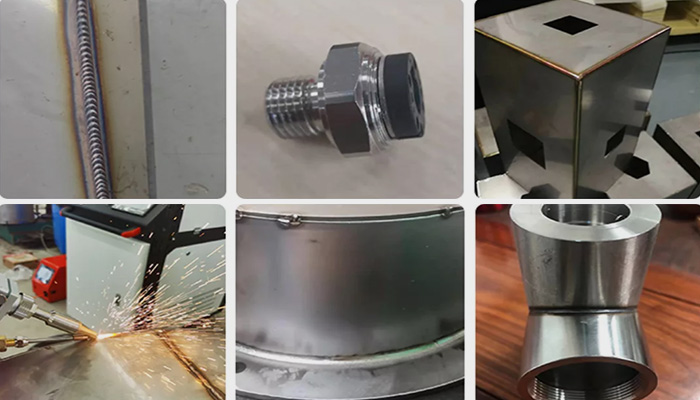

Laser welding machine is mainly used for aluminum tubes, copper tubes, pipe joint, air conditioner, valves, home appliance metal parts brazing welding jobs, we can custom all kinds of different welding systems as request.

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: bullet case and pipes

Product specifications: φ10-20mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Melting equipment is mainly used for the steel, alloy steel, cast iron and other ferrous metal materials and stainless steel, copper, aluminum, zinc and other non-ferrous metal material smelting.

Fill in the information and we will contact you as soon as possible