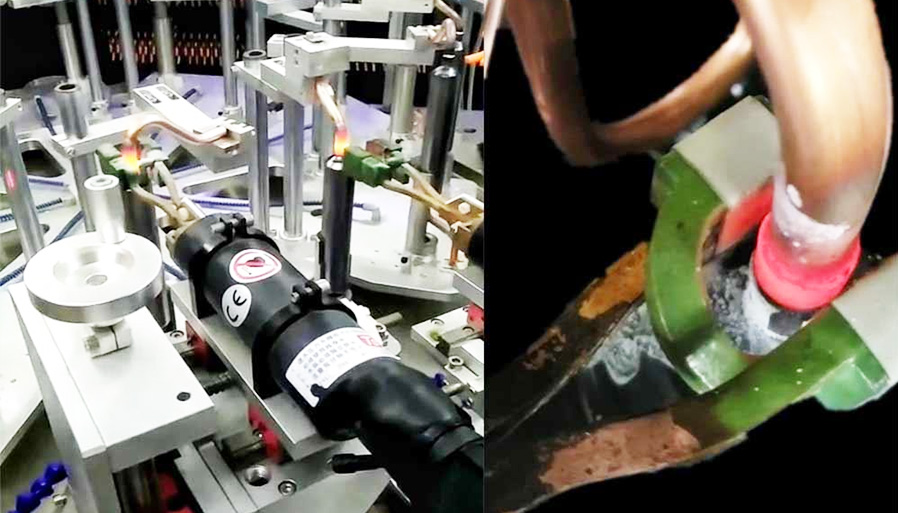

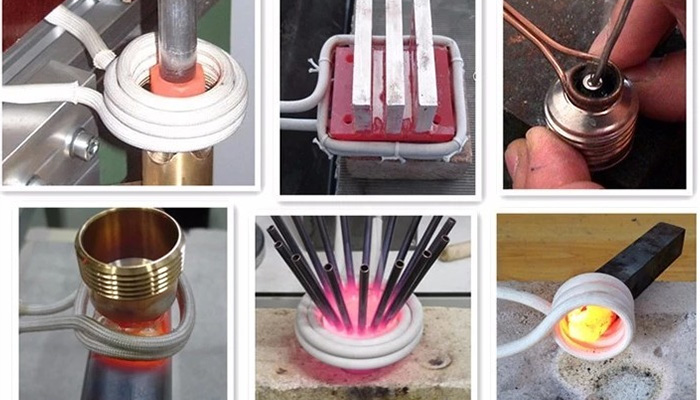

Digital induction heating machine adopts IGBT digital control system, equipped with small volume and light weight of the coaxial transformer. Especially for supporting industrial robots, manual hand-held induction heating. Widely used in brazing, curing, thermal expansion, hardening, straightening, etc.

1. Constant current mode precise control , current fluctuation no more than 0.5A, high repetition accuracy, basically no deviation.

2. Continuous segment heating

3. Complete protection functions, under pressure, over current,etc

4. Convenient to communication with PLC and computer

|

Model |

FH-M25 |

FH-M40 |

FH-M50 |

FH-M60 |

|

|

Input power |

Voltage |

360-420V |

|||

|

Continuous input current |

15A |

24A |

30A |

36A |

|

|

Power supply output |

Maximum output power |

15KW |

25kW |

32kW |

40KW |

|

Output frequency |

20-50KHZ |

||||

|

Cooling water |

Water flow |

2L/min |

4L/min |

6L/min |

7L/min |

|

Water pressure |

4-8Bar |

||||

|

Maximum inlete temperature |

32℃ |

||||

|

Coaxial transformer |

size |

Φ50*160mm |

Φ80*160mm |

||

|

Flexible cable length |

2-10m |

||||

1. Color screen display: display the heating current curve, frequency, heating time,etc

2. Has multi-function buttons: realize fast parameters setting

3. Fully closed induction heating box design: has clean working environment

4. Rich interface form: Working well with PLC and automatic systems

5. Induction coil: special design ,easy to install

6. Flexible water cable: length can be customized, normally 2-10m

Digital induction heating machine is mainly used in the appliance industry, machinery manufacturing industry, medical equipment industry, hardware industry, aerospace industry, refrigeration and heating and ventilation industry, all kinds of pipes, tubes, and other metal parts automatic induction brazing work, suitable for mass production, high work efficiency.

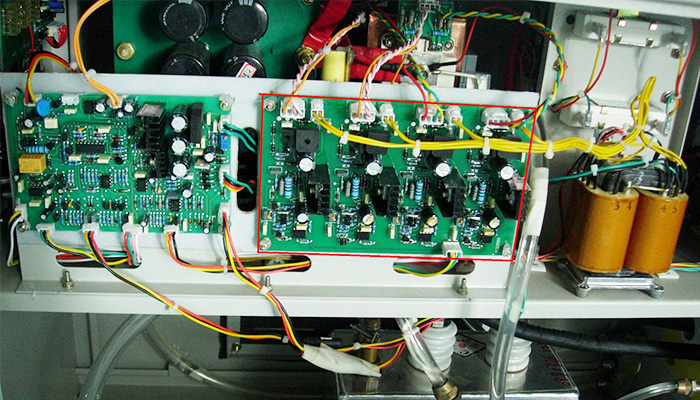

The Siemens IGBT (Insulated gate Bipolar transistor) circuit module is a key component used in a wide range of power electronic devices, mainly for efficient energy conversion and control. Circuit module: The IGBT chip, drive circuit, protection circuit, etc. are integrated in a package for easy use.

Get Started

The control board is one of the core components of the induction heating equipment, which is responsible for managing and regulating the operating state of the equipment to ensure the accurate control of the heating process.

Get Started

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Fill in the information and we will contact you as soon as possible