● Digital design

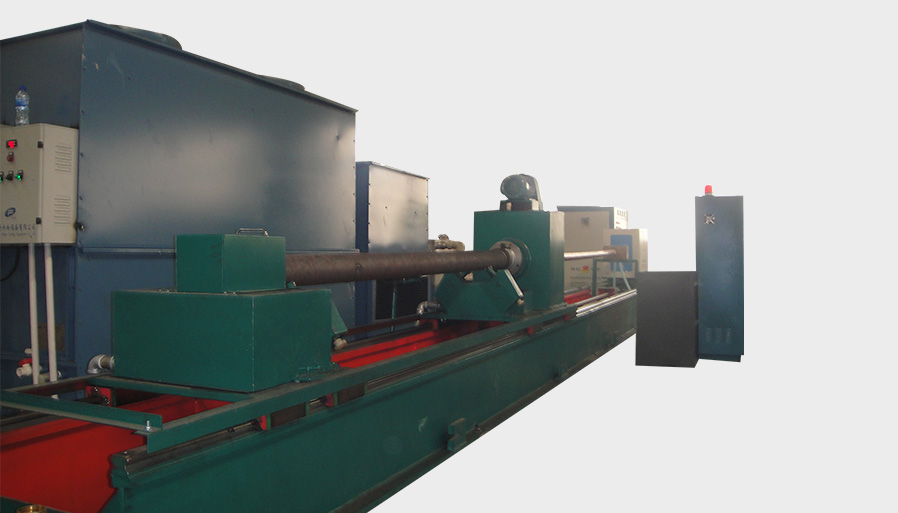

● High strength welding machine tool body.

● Stainless steel machine tooltips.

● With patented induction hardening transformer.

● All imported ball screw.

● The part clamp length can be electrically adjusted.

● The rotation control mode: Frequency converter/stepper motor/AC servo motor.

1. The workpiece rise and down, transformer move back and front all adopt servo motor drives, ball screw transmits, the moving position can be accurately controlled.

2. With 1 station or 2 station working position.

3. According to the workpiece moving speed, change different power levels.

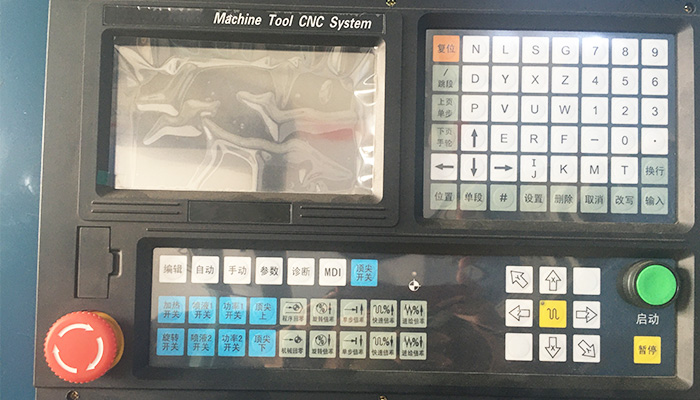

4. Can display, record, and store the induction heat treatment working process technical parameters timely.

5. Easy to adjust the hardening process, easy to operate.

|

Model |

FHSL350 |

FHSL550 |

FHSL850 |

FHSL1050 |

FHSL1250 |

|

Max. Clamp length(mm) |

350 |

550 |

850 |

1050 |

1250 |

|

Max.Hardening part(mm) |

300 |

500 |

800 |

1000 |

1200 |

|

Part swing diameter (mm) |

400 |

400 |

400 |

400 |

400 |

|

Part weight(kg) |

30 |

30 |

50 |

200 |

200 |

|

Rotating speed (rpm) |

20-150 |

||||

|

Parts/ induction coil moving speed(mm/s) |

0-80 |

||||

|

Spindle number |

1/2 |

||||

|

Center distance between two stations |

650 |

||||

Our double station CNC induction hardening machine with double station vertical structure. Can choose workpiece movement and induction coil movement methods.

Match with the digital induction heating system and the humanized control system, the double-station vertical workpiece mobile quenching machine can be applied to the production of single and batch parts, with reasonable structure.Mainly used for the crankshaft, small diameter disc parts, etc.

1.Is it green for the environment?

Yes, our machine meets the environment protection requirement, low pollution, low consumption.

2.How to provide the professional induction annealing machine?

We have a strong technical team that will do many times tests according to your technical request. Until test is OK and then suggest suitable induction annealing machine to you.

3.What is your advantage compared to other company’s machine?

Our machine has excellent reliability 100% solid state design. We are manufacturer with a strong technical team for 19 years experiences and supply hundreds of induction heating technical schemes and machines.

4.How about the heating forging result?

The parts is heated uniformly, and temperature control precision is high.

The workpiece holding device of the quenching machine tool is the key component to ensure the stable position and attitude of the workpiece during the quenching process. Its functions are fixed workpiece, accurate positioning, fast loading and unloading. It is essential to ensure the stability and accuracy of the workpiece during the quenching process.

Get Started

The PLC automatic control display is the core part of the control system and is used to monitor and operate the quenching process. Its functions include real-time monitoring, operation control, fault alarm and data recording.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible