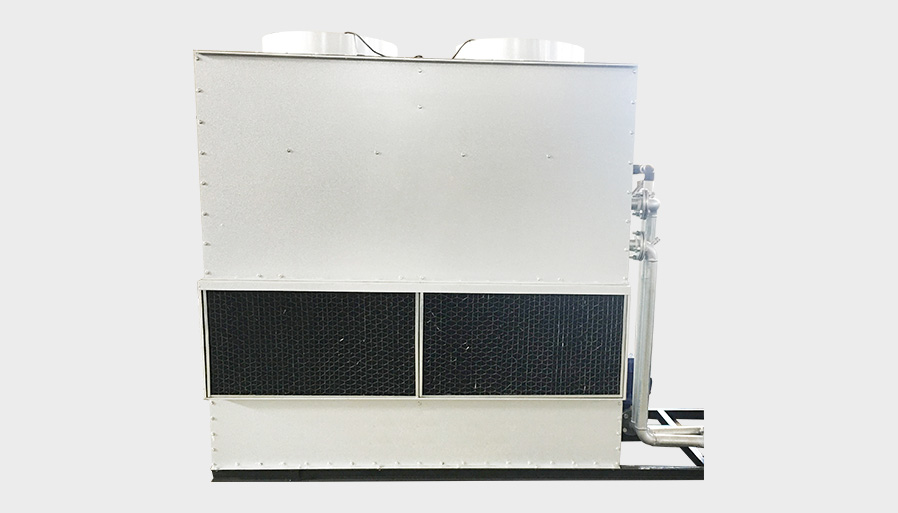

Closed loop cooling water machine (also known as closed cooling tower, or closed cooling tower) is a tube heat exchanger placed in the tower to ensure the cooling effect through the heat exchange of circulating air, spray water outside the pipe, and circulating water inside the pipe. Because the circulating water is closed in the pipe, it can guarantee the water quality from pollution, protect the efficient operation of the main equipment, and improve the service life. When the outside air temperature is low, the sprinkler system can be stopped to save water. With the implementation of a national policy of energy conservation and emission reduction and the shortage of water resources, a closed cooling tower has been widely used in steel metallurgy, power electronics, mechanical processing, air conditioning system, and other industries in recent years.

● High-efficiency water collector, control operation drift water rate ≤0.001%.

● High air duct design, to ensure that the equipment operating air volume to meet the heat dissipation requirements.

● The device is small in size, occupies little space, and is easy to move and replace.

● Automatic intelligent control is adopted, and the cooling mode can be changed automatically according to the requirements of working conditions. The closed-loop water cooling systems operation is simple and reliable.

|

model |

BL-01 |

BL-02 |

BL-04 |

BL-06 |

BL-08 |

|

Cooling capacity |

50000 |

100000 |

150000 |

200000 |

250000 |

|

58 |

116 |

174 |

233 |

291 |

|

|

Circulating water flow rate(m3/h) |

10 |

20 |

30 |

40 |

50 |

|

Cooling Fan power |

0.75 |

2.2 |

1.5X2 |

1.5X2 |

1.5X2 |

|

Main circulation pump power(KW) |

2.2 |

4 |

4 |

5.5 |

7.5 |

|

Water inlet and outlet pipe Φ |

DN50 |

DN65 |

DN65 |

DN80 |

DN80 |

|

Chilled Tank Capacity |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

|

Weight (KG) |

490 |

816 |

1090 |

1250 |

1300 |

● Induction heating and metal smelting equipment, such as high frequency, medium frequency induction heating power supply, induction diathermy furnace, annealing furnace, quenching equipment, melting furnace, return furnace, heat preservation furnace, and other heat treatment production cooling.

● Cooling of circulating water in various reactors and condensers in the chemical industry.

● Cooling of the large motor, diesel engine, rectification equipment, electric welding equipment, hydraulic station, and continuous casting equipment, etc.

● Metal die casting mold, injection mold, and other large mold cooling.

● Industrial solution cooling, such as quenching liquid, electroplating liquid, etc.

1. Factory direct delivery goods and no agent.

2. 24 hours of technical service online

3. Free workpiece test and send test video to you.

4. 19 year experience in product making and application

5. In stock, 12 months warranty periods

6. Lifetime technical and accessory support

The fan is a key component in the chiller system, which is mainly used for heat dissipation and temperature maintenance.

Get Started

The water pump is the core component of the chiller system, which is responsible for circulating cooling water to ensure the normal operation of the system. It mainly plays the role of water circulation and heat exchange.

Get Started

The fan blade is the core component of the fan system, which directly affects the heat dissipation efficiency and system performance. Reasonable selection and regular maintenance can improve the efficiency and life of the chiller.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product Name: Wire

Product specifications: φ5-20mm

Product name: Thick steel plate

Product specifications: 1000×100mm

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Fill in the information and we will contact you as soon as possible