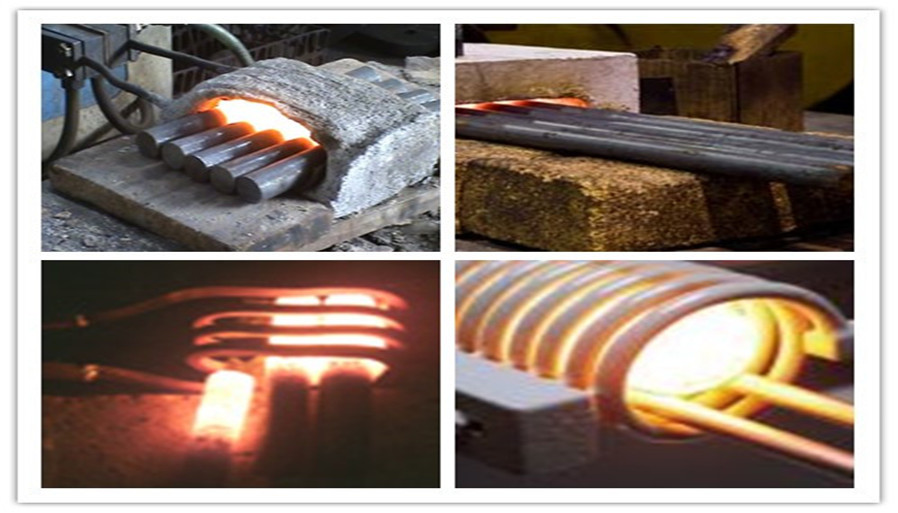

We have many years experiences for billet induction forging furnace. The standard forging system includes the heating forging part, material loader and unloader part, forging furnace part, cooling water tower, and material store bus. Our machine is mainly used in round bar, square billet heating forging.

1. Frequency range is 20-100KHZ

2. When the whole billet forging, the medium frequency induction coil length is 500mm-1m, heat several pieces of the bar at the same time to ensure the forging consult.

3. Medium frequency induction forging furnace adopts the continuous heating method, the induction coil inside load is uniform. During the heating process, single bar feed load rises from room temperature to 1100 degrees, the huge load changes cause the machine actual power changes. The machine actual power need guarantee to above 85% of the rated power in the whole continuous heating process.

4. Compared to SCR, it is not only small in size, easy to maintain but also can save 15%-20% power. /p>

|

Forging model |

Heat steel or stainless steel to 1050° |

Heat copper to 700° |

|

FHZ-35 |

1.25KG/minute |

1.75KG/minute |

|

FHZ-70 |

2.5KG/minute |

3.5KG/minute |

|

FHZ-110 |

4.17KG/minute |

5.83KG/minute |

|

FHZ-160 |

5.83KG/minute |

|

|

FHZ-250 |

8.6KG/minute |

|

|

FHZ-300 |

11.25KG/minute |

|

|

FHZ-500 |

17.9KG/minute |

Billet induction forging machine is used for above diameter 12mm steel, stainless steel, copper and aluminum material round bar, square bar,etc continuous heating forging. Not only can use for the whole billet forging but also can use for partial forging,like billet end forging, billet middle part forging and so on.

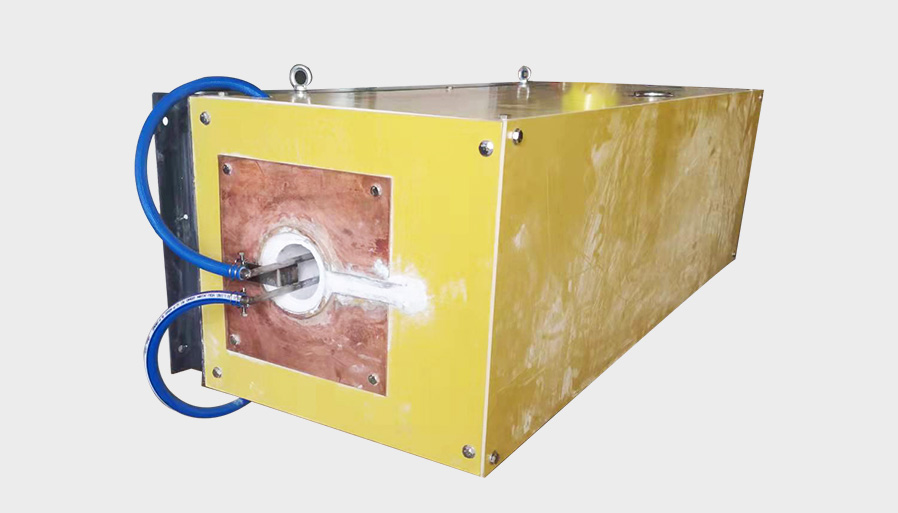

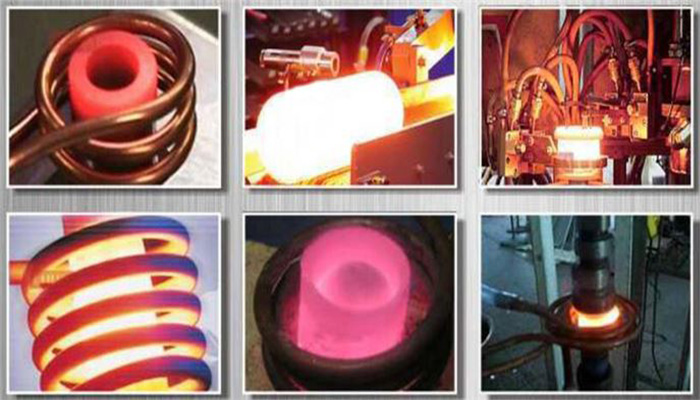

Induction forging furnace is the core component of induction heating equipment, which is responsible for generating alternating magnetic field to induce eddy current inside the metal workpiece and heat. Main structure: Coil material: usually high conductivity copper pipe, internal cooling water to prevent overheating. Coil shape: According to the shape of the workpiece design, common spiral shape, flat shape, ring and so on. Insulation: The coil surface is coated with insulation to prevent short circuits and arcing.

Get Started

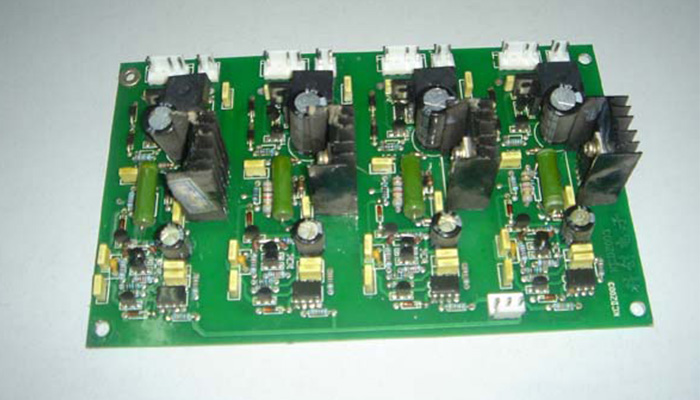

The filter circuit is an important part of ensuring the stable operation of equipment and reducing electromagnetic interference (EMI).

Get Started

The drive board is one of the core components of induction heating equipment, which is responsible for controlling the power output and heating process.

Get StartedDSP High frequency induction heating machine heating power supply is adopted, and the main inverter circuit is controlled separately.

Product name: Car anti-collision bar

Product specifications: φ35×1300mm

Product name: bullet case and pipes

Product specifications: φ10-20mm

Adopts series resonance technique, High frequency induction heating machine coil output high voltage and small current, resonance circuit loss is average lower 25 times than parallel resonance, whole machine save energy 10-20%.

Setting in the fully automatic mode, the workpiece into the tooling, the material position detecting sensor to the signal sent to PLC, PLC in accordance with the procedures set automatically.

Fill in the information and we will contact you as soon as possible